Overview

The article presents four crucial steps for noise abatement at drilling sites. It begins by emphasizing the need to understand legal requirements, which is vital for compliance and avoiding potential penalties. Next, it focuses on identifying noise sources, a critical aspect that allows for targeted interventions. The implementation of control measures follows, showcasing effective strategies for minimizing sound pollution. Finally, the article highlights the importance of regularly monitoring noise levels to ensure ongoing compliance and community satisfaction. Each step underscores the necessity of adhering to regulations and fostering positive relationships with surrounding communities, ultimately contributing to a safer and more productive work environment.

Introduction

Navigating the complexities of noise abatement at drilling sites is not merely a regulatory requirement; it is essential for maintaining community relations and ensuring worker safety. Given that drilling operations often produce sound levels exceeding safe thresholds, it is imperative to understand the legal landscape and implement effective noise control measures. However, how can operators achieve compliance while enhancing operational efficiency and minimizing environmental impact? This article outlines four essential steps for effective noise abatement, offering practical strategies aimed at fostering a quieter, safer, and more responsible drilling operation.

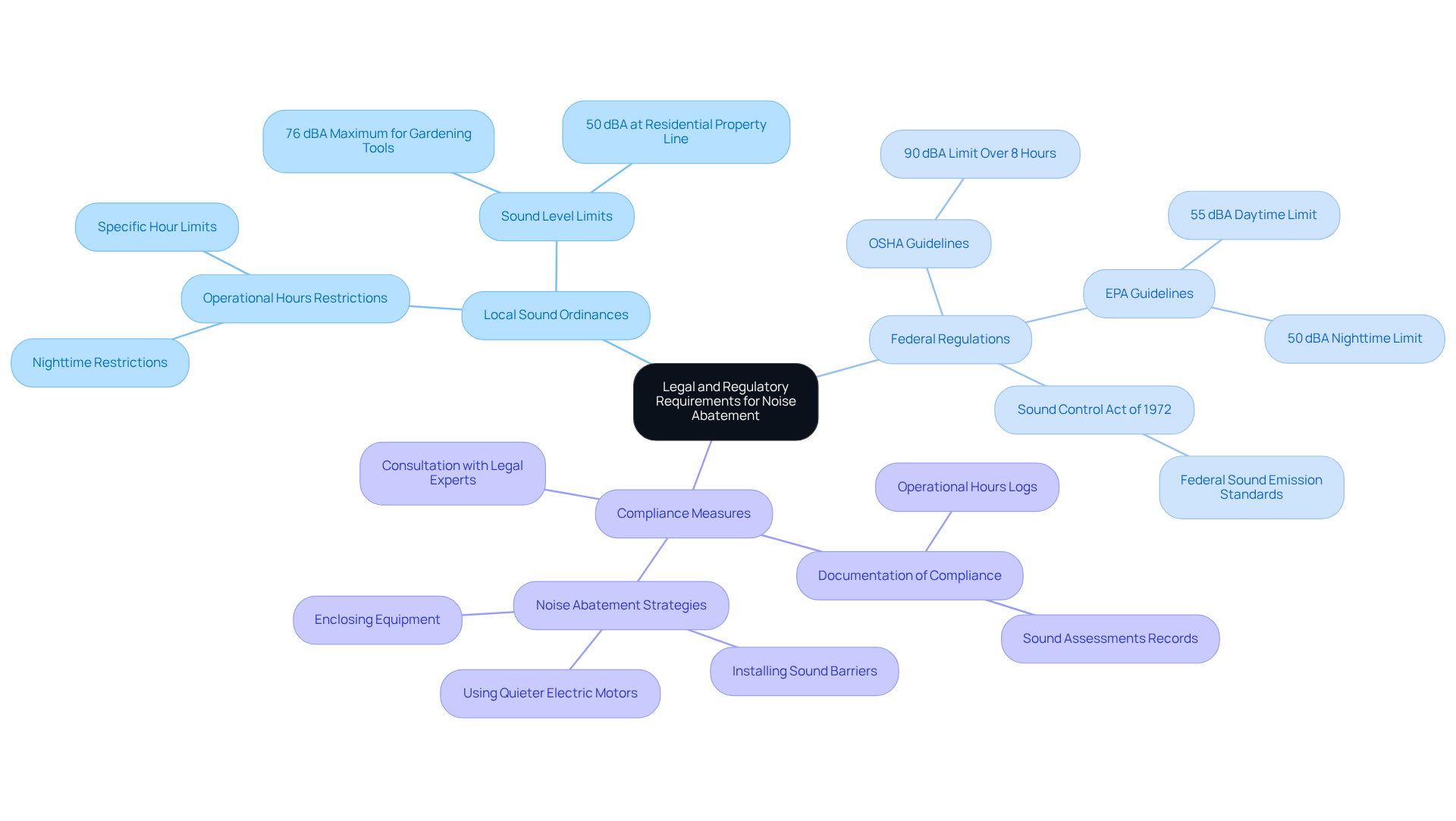

Understand Legal and Regulatory Requirements

Understanding the legal and regulatory environment is crucial for effective noise abatement at drilling sites. Begin by investigating local sound ordinances and regulations related to noise abatement at drilling sites, as these can vary significantly by region. Regulatory bodies such as OSHA and the EPA establish specific sound intensity limits, which includes guidelines for noise abatement at drilling sites, mandating that sound exposure should not exceed 90 dBA over an 8-hour workday to protect workers' hearing. Additionally, the EPA has established guidelines for noise abatement at drilling sites, requiring sound levels to be controlled to prevent disturbances in residential areas, typically setting limits around 55 dBA during the day and 50 dBA at night. The Sound Control Act of 1972 further underscores the necessity for noise abatement at drilling sites, establishing a framework for federal sound emission standards.

Operational hours must comply with local restrictions on noise-generating activities. Many municipalities enforce strict limits on when drilling can take place, particularly during nighttime, to ensure noise abatement at drilling sites and minimize disturbances to nearby residents. For instance, in Torrance, California, the use of power gardening tools is restricted to specific hours, with a maximum volume of 76 dBA allowed at the airport, highlighting the importance of adhering to local regulations.

It is essential to document all compliance measures meticulously. Maintain detailed records of sound assessments, operational hours, and any mitigation strategies employed. Notably, sound levels exceeding the ambient sound level at the property line of any residential land by more than 5 decibels are considered a prima facie violation. This documentation will be invaluable during inspections and can demonstrate compliance with regulations.

In situations where regulations are unclear or complex, consulting with legal experts can provide clarity and ensure that all operational practices are compliant. This proactive approach not only aids in adhering to sound regulations but also promotes noise abatement at drilling sites, fostering positive relationships with the community and regulatory agencies. Operators are encouraged to implement various strategies for noise abatement at drilling sites, including:

- Installing sound barriers

- Enclosing equipment in sound-insulated buildings

- Substituting loud motors with quieter electric alternatives

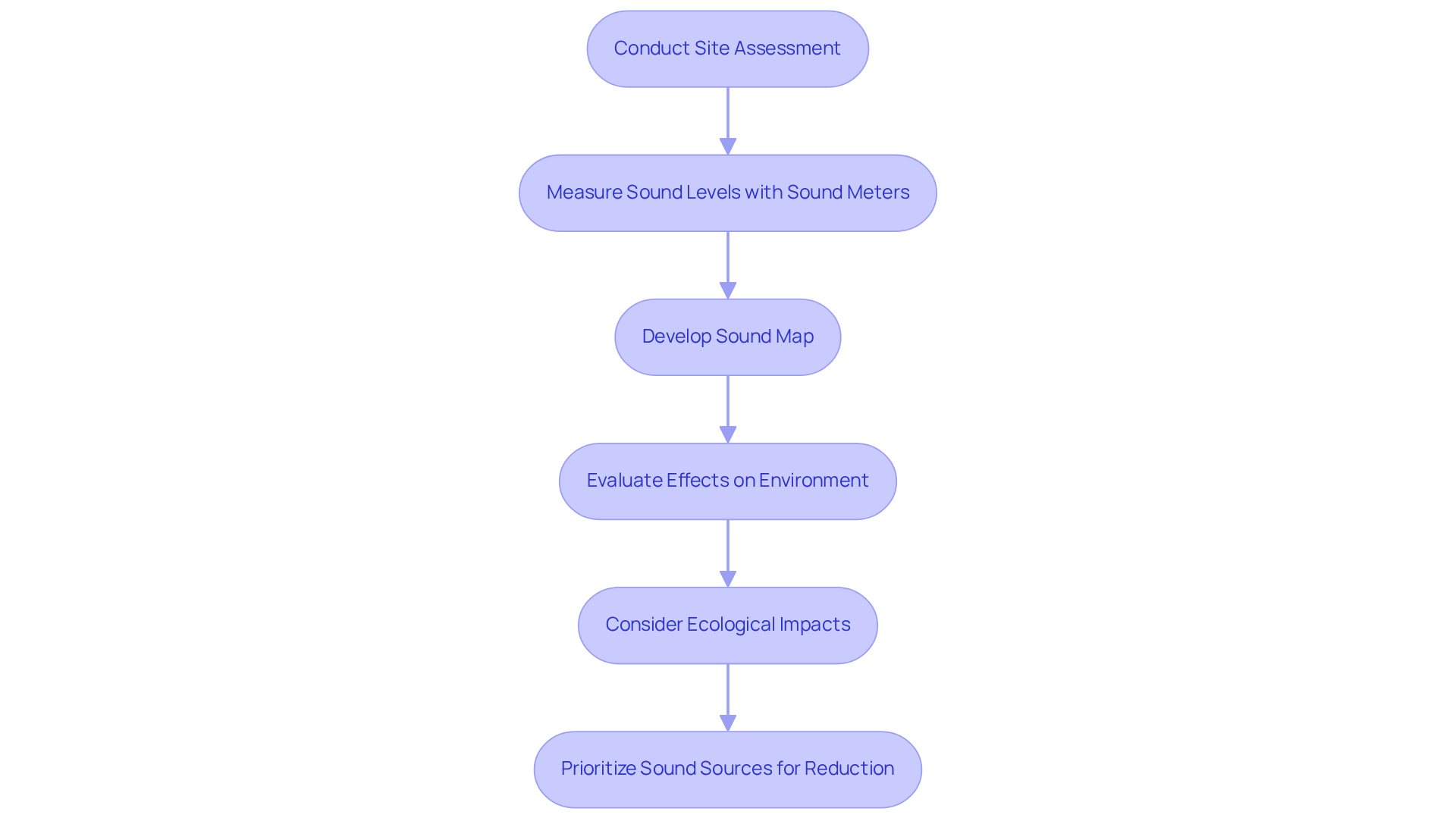

Identify and Assess Noise Sources

- Conduct a thorough site assessment to pinpoint all potential sound sources, such as boring machines, compressors, and vehicle movement. Research indicates that drilling activities can produce sound levels averaging 83 dBA, while gas compressors can reach up to 89 dBA. Identifying these contributors is crucial for effective noise abatement at drilling sites.

- Employ sound level meters to accurately measure sound levels at various locations throughout the site. These devices are vital for evaluating sound intensity and ensuring compliance with regulatory standards. Sound engineers emphasize that precise measurements are essential for effective sound control.

- Develop a comprehensive sound map to illustrate areas of heightened sound concentration. This mapping is vital for understanding the spatial distribution of sound and its potential impact on nearby communities and wildlife.

- Evaluate the effects of identified sound sources on surrounding environments. Research has shown that prolonged exposure to sound levels exceeding 65 dBA can lead to health issues such as stress, sleep disturbances, mental and physical fatigue, and irreversible hearing impairment, which emphasizes the necessity of noise abatement at drilling sites and thorough evaluation.

- Take into account the ecological impacts of sound pollution, as it can interfere with wildlife communication and contribute to population declines.

- Prioritize sound sources based on their overall impact on sound levels. By focusing on the most significant contributors, operators can effectively implement targeted sound reduction strategies for noise abatement at drilling sites, such as installing sound barriers or mufflers to minimize sound emissions.

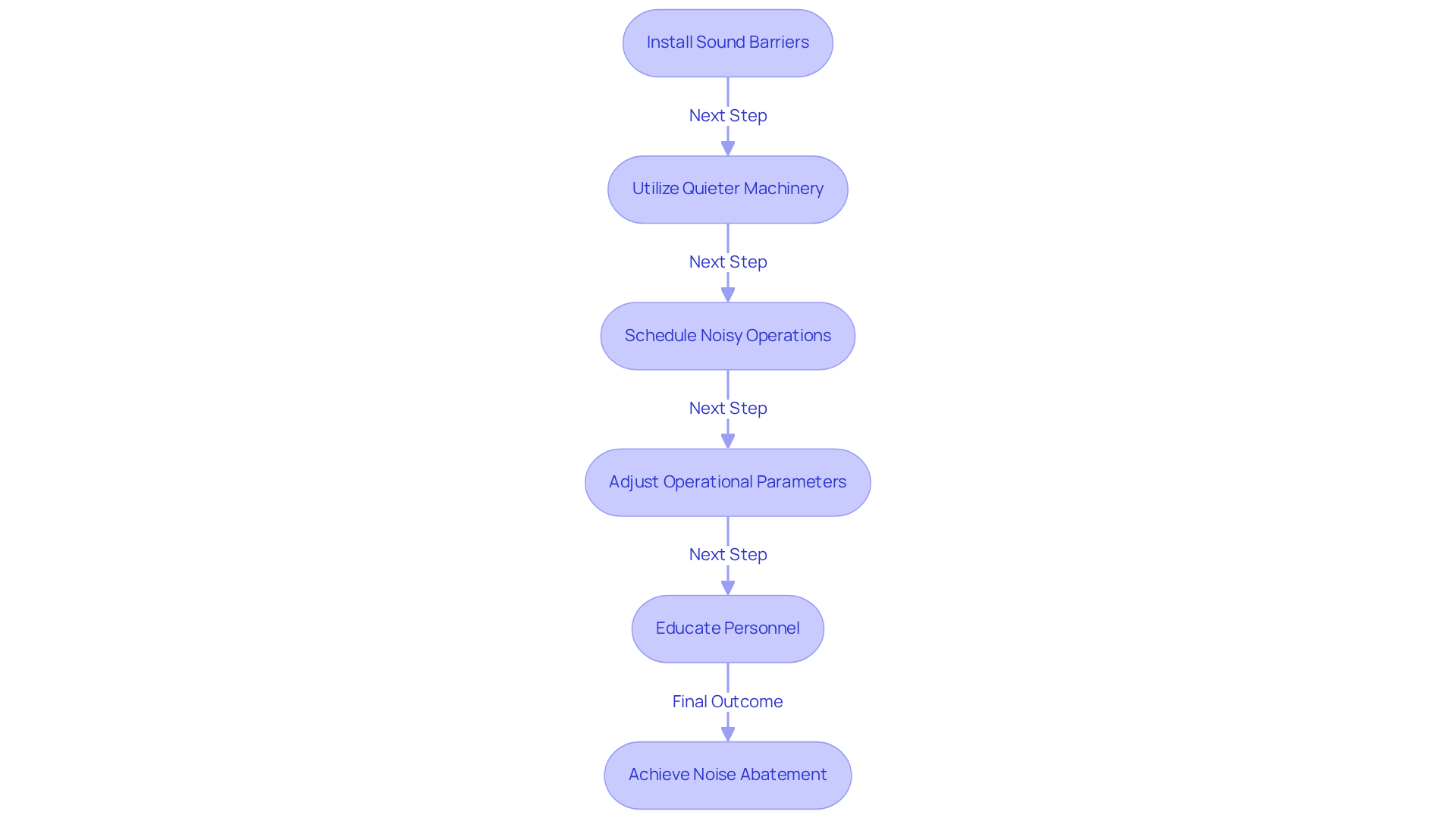

Implement Effective Noise Control Measures

To achieve noise abatement at drilling sites, it is important to install sound barriers or acoustic enclosures around high-volume equipment to significantly reduce sound transmission. These barriers can lower sound levels by up to 66 dB, fostering a safer and more comfortable working environment. Additionally, sound-absorbing panels enhance employee exposure to sound, ultimately boosting comfort and productivity.

Whenever possible, utilize quieter machinery and equipment. Research indicates that implementing quieter technologies can lead to a substantial reduction in sound exposure, thereby improving employee comfort and productivity. Notably, studies show that employees exposed to sound intensities of 90 dB experience a 34% decrease in problem-solving capacity, underscoring the importance of quieter technologies.

To achieve noise abatement at drilling sites, schedule noisy operations during less sensitive hours to minimize disturbances to nearby communities. This practice not only helps maintain positive relations with residents but also complies with local sound regulations.

Implement operational changes, such as reducing drilling speeds, to support noise abatement at drilling sites. Adjusting operational parameters can effectively mitigate disturbances without sacrificing productivity.

Educate personnel on sound reduction techniques and the importance of adhering to control measures. By informing staff about the effects of sound and the benefits of following sound control protocols, you promote a culture of safety and accountability on-site. Extended exposure to elevated sound conditions can lead to persistent health issues like hypertension and anxiety, making it crucial to emphasize sound management.

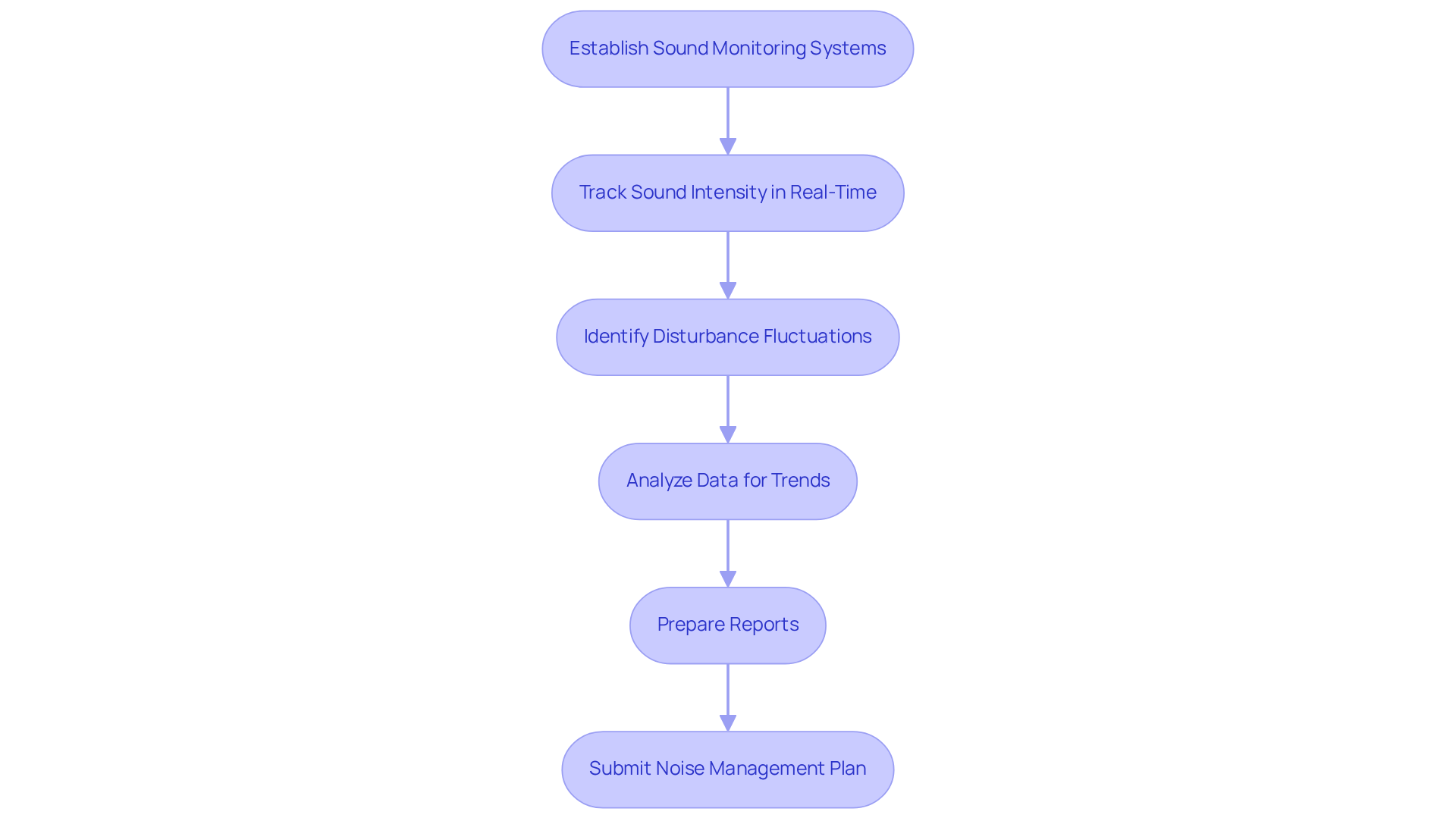

Monitor Noise Levels Regularly

Establishing ongoing sound monitoring systems is essential for noise abatement at drilling sites to track sound intensity in real-time. These systems enable the prompt identification of disturbance fluctuations, ensuring compliance with regulatory limits. For example, the Colorado Oil and Gas Conservation Commission mandates that sound levels must not exceed specific decibel thresholds based on property use, underscoring the importance of proactive monitoring as regulations evolve in 2025. Routine sound evaluations are vital for assessing adherence to these limits.

Analyzing data from these monitoring systems can reveal trends and potential issues, allowing operators to address sound concerns before they escalate. Environmental advisors emphasize that continuous sound monitoring not only aids in compliance but also fosters community trust by demonstrating a commitment to minimizing environmental impacts. As Dr. Keman Liu notes, advancements in electromagnetic measurement technologies can enhance the efficacy of sound monitoring systems.

Effectively communicating findings to stakeholders is crucial. This includes preparing detailed reports that outline adherence status and any necessary adjustments to sound management strategies. Such transparency is vital for regulatory compliance and nurturing positive relationships with local communities. Furthermore, prior to permit approval, oil companies are required to submit a Noise Management Plan, which is critical for understanding regulatory compliance and ensuring effective noise abatement at drilling sites.

Conclusion

Understanding the complexities of noise abatement at drilling sites is essential for regulatory compliance and fostering positive community relations. Effective noise management not only safeguards worker health but also minimizes disturbances to nearby residents, promoting a harmonious coexistence between drilling operations and local environments.

The article presents a comprehensive four-step approach to achieving effective noise abatement:

- It underscores the importance of comprehending legal and regulatory requirements, which encompass adherence to local sound ordinances and meticulous documentation.

- It emphasizes the necessity of identifying and assessing noise sources through thorough site evaluations and sound mapping.

- The third step centers on implementing effective noise control measures, such as employing quieter machinery and strategically scheduling operations.

- Lastly, the article highlights the need for ongoing monitoring of noise levels to ensure compliance and proactively address any emerging issues.

By adopting these strategies, drilling operators can significantly reduce their noise footprint. This commitment to noise abatement transcends regulatory obligation; it is a crucial step toward fostering a sustainable and responsible drilling industry. Engaging with communities, investing in quieter technologies, and maintaining transparency in noise monitoring will ultimately lead to a more favorable perception of drilling operations and contribute to environmental stewardship.

Frequently Asked Questions

Why is it important to understand legal and regulatory requirements for noise abatement at drilling sites?

Understanding legal and regulatory requirements is crucial for effective noise abatement at drilling sites, as it helps ensure compliance with local sound ordinances and protects workers' hearing.

What specific sound intensity limits are established by OSHA and the EPA for drilling sites?

OSHA and the EPA mandate that sound exposure should not exceed 90 dBA over an 8-hour workday to protect workers' hearing, while the EPA typically sets noise level limits around 55 dBA during the day and 50 dBA at night to prevent disturbances in residential areas.

What is the Sound Control Act of 1972, and how does it relate to noise abatement?

The Sound Control Act of 1972 establishes a framework for federal sound emission standards, emphasizing the necessity for noise abatement at drilling sites.

Are there local restrictions on operational hours for drilling activities?

Yes, many municipalities enforce strict limits on when drilling can occur, particularly during nighttime, to minimize disturbances to nearby residents.

What documentation is required to demonstrate compliance with noise regulations?

Operators must maintain detailed records of sound assessments, operational hours, and any mitigation strategies employed, as sound levels exceeding the ambient sound level at the property line of residential land by more than 5 decibels are considered a violation.

What should operators do if they find regulations unclear or complex?

In such cases, operators should consult with legal experts to ensure all operational practices are compliant with regulations.

What strategies can be implemented for noise abatement at drilling sites?

Strategies for noise abatement include installing sound barriers, enclosing equipment in sound-insulated buildings, and substituting loud motors with quieter electric alternatives.

List of Sources

- Understand Legal and Regulatory Requirements

- Chapter 6 NOISE REGULATION (https://codepublishing.com/CA/Torrance/html/Torrance04/Torrance0406.html)

- Summary of the Noise Control Act | US EPA (https://epa.gov/laws-regulations/summary-noise-control-act)

- Oil and Gas Noise - Earthworks (https://earthworks.org/issues/oil-and-gas-noise)

- Municode Library (https://library.municode.com/tx/houston/codes/code_of_ordinances?nodeId=COOR_CH30NOSOLERE)

- Identify and Assess Noise Sources

- Oil and Gas Noise - Earthworks (https://earthworks.org/issues/oil-and-gas-noise)

- Fracking: Noise Pollution (https://indivisibleventura.org/fracking-noise-pollution)

- (PDF) Noise Assessment for onshore oil gas drilling (5).doc Edited (https://researchgate.net/publication/330713399_Noise_Assessment_for_onshore_oil_gas_drilling_5doc_Edited)

- Residential noise from nearby oil and gas well construction and drilling - PubMed (https://pubmed.ncbi.nlm.nih.gov/29749380)

- Implement Effective Noise Control Measures

- Hushtec – A Customisable and High-Performing Noise Reduction Solution Tailored for Construction and Demolition Sites (https://hushtecsolutions.com/au/the-impact-and-applications-of-permanent-noise-walls-in-urban-and-industrial-settings)

- Effective Noise Reduction Solutions for Commercial and Industrial Environments (https://soundfighter.com/effective-noise-reduction-solutions)

- What is Industrial Noise and How to Control It? | MECART Noise Control (https://mecart.com/blog/2025/03/20/what-is-industrial-noise-and-how-to-control-it)

- Noise Barrier - an overview | ScienceDirect Topics (https://sciencedirect.com/topics/earth-and-planetary-sciences/noise-barrier)

- Monitor Noise Levels Regularly

- Drilling Rig Noise Control (https://noisemonitoringservices.com/drilling-rig-noise-control-4062)

- Experimental Study of Statistical Characteristics of the High-Frequency Vibrations of a Drill-String Bottom - Radiophysics and Quantum Electronics (https://link.springer.com/article/10.1007/s11141-024-10338-3)

- Drilling site noise evaluation technology promote the performance of EM-MWD system - Advances in Engineering (https://advanceseng.com/drilling-site-noise-evaluation-technology-promote-performance-em-mwd-system)

- Statistical Methods to Improve the Quality of Real-Time Drilling Data (https://asmedigitalcollection.asme.org/energyresources/article/144/9/093006/1131342/Statistical-Methods-to-Improve-the-Quality-of-Real)