Overview

The article presents four essential strategies for achieving success in coastal wind turbine maintenance:

- Establishing regular maintenance protocols

- Implementing comprehensive maintenance activities

- Leveraging data-driven strategies

- Adopting specialized techniques for offshore maintenance

Each strategy is substantiated by evidence and case studies that illustrate improvements in operational efficiency, cost reduction, and enhanced safety. This underscores the significance of systematic and innovative approaches to maintaining wind turbine performance.

Introduction

Coastal wind turbines are essential to the renewable energy landscape, yet their maintenance presents a complex challenge. Effective upkeep strategies not only enhance operational efficiency but also protect substantial investments in this clean energy sector. How can operators ensure these towering structures remain reliable and efficient? This article explores four critical strategies for coastal wind turbine maintenance, providing insights that will aid operators in navigating the intricacies of upkeep while maximizing performance and minimizing downtime.

Establish Regular Maintenance Protocols for Wind Turbines

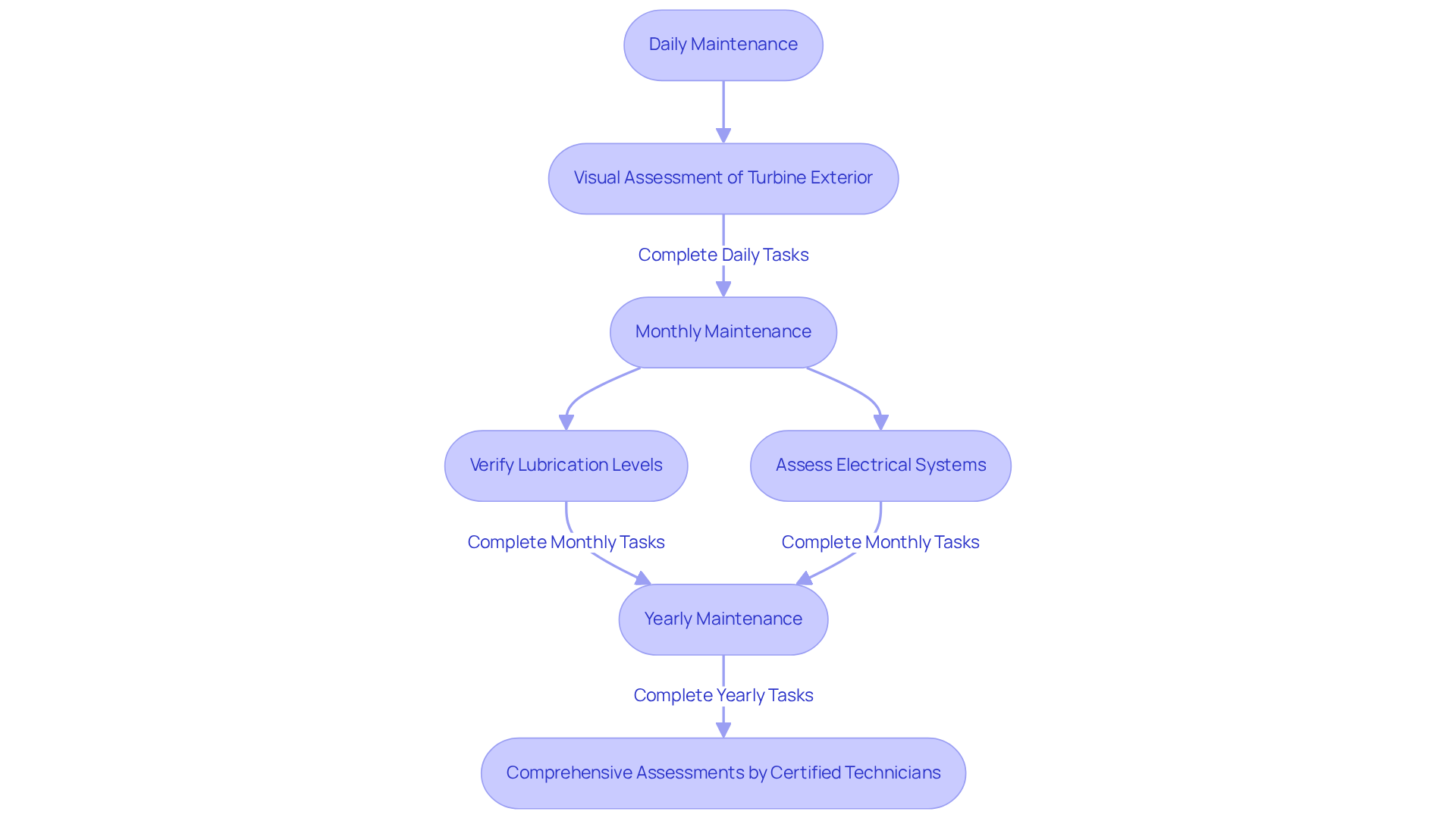

To establish effective coastal wind turbine maintenance protocols, operators must create a comprehensive schedule that includes daily, monthly, and annual inspections. Daily checks should focus on visual assessments of the turbine's exterior, including blades and nacelle, to promptly identify any immediate issues. Monthly upkeep involves more detailed inspections, such as verifying lubrication levels and assessing electrical systems. Yearly upkeep requires comprehensive assessments of all mechanical parts, including gearboxes and generators, performed by certified technicians. Utilizing checklists ensures that all necessary tasks are completed systematically, minimizing the risk of oversight.

Integrating predictive upkeep strategies facilitates ongoing observation of each generator, allowing for preventive actions before problems escalate. This approach not only enhances efficiency but also reduces costs associated with unscheduled repairs. Furthermore, the incorporation of remote control technologies enables centralized oversight and management of generators, enhancing operational efficiency and decreasing the need for on-site visits, which is particularly advantageous for upkeep scheduling in remote areas.

Consider the example of a wind farm in Texas that implemented a strict upkeep schedule, resulting in an impressive 20% rise in operational efficiency over two years. This case exemplifies the concrete advantages of adopting regular upkeep protocols, highlighting their essential role in improving performance and reliability through coastal wind turbine maintenance. By avoiding common pitfalls linked to upkeep practices, such as unnecessary servicing or incidental damage, operators can further enhance their repair strategies, leading to improved reliability and reduced downtime.

Implement Comprehensive Maintenance Activities

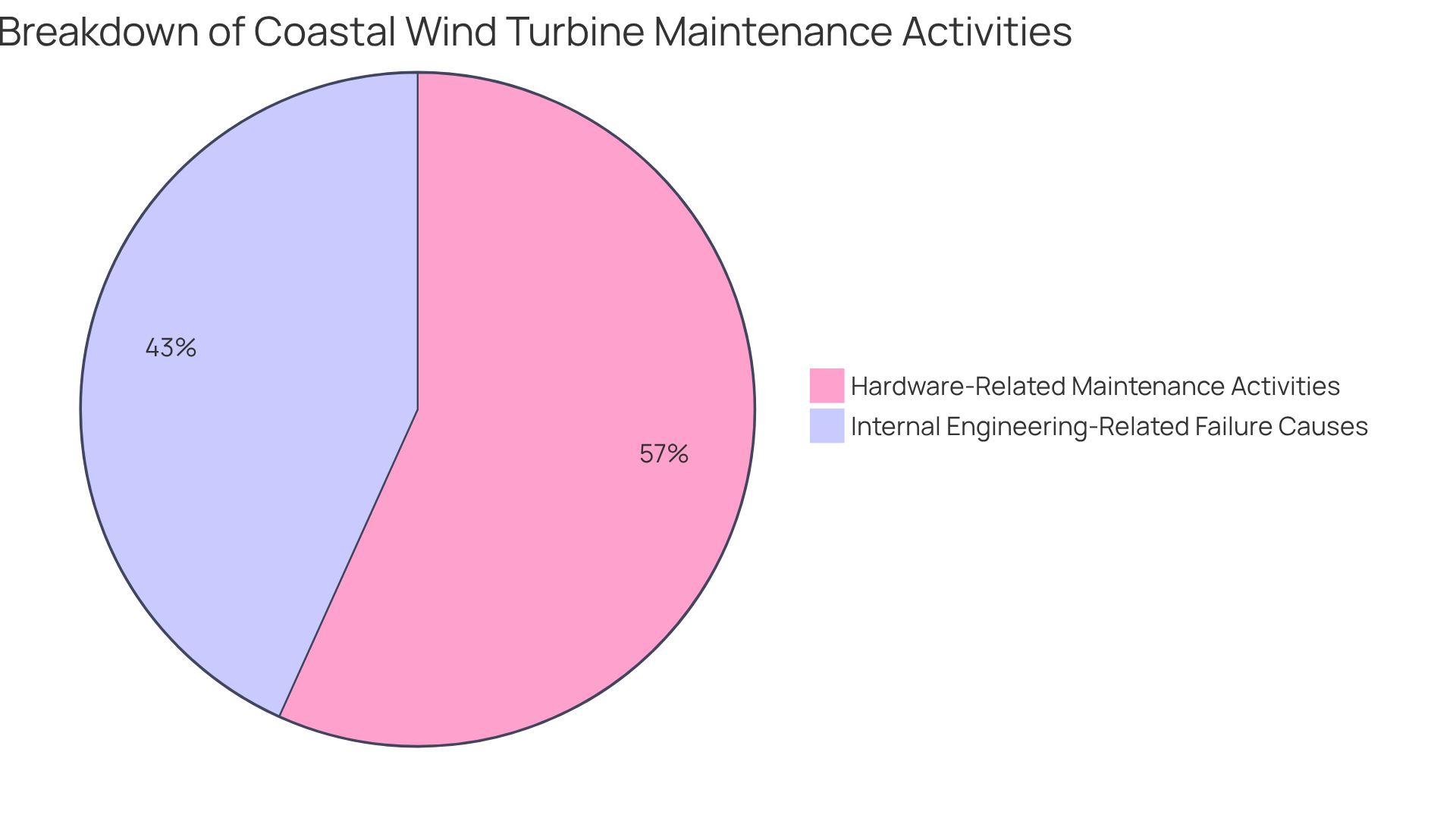

Thorough upkeep tasks for coastal wind turbine maintenance must encompass both preventive and corrective actions. Routine tasks such as lubrication, tightening bolts, and inspecting electrical systems are crucial for prolonging the lifespan of turbine components, which are all part of coastal wind turbine maintenance. Notably, approximately 82.5% of all upkeep activity is hardware-related, underscoring the significance of these routine tasks. In contrast, coastal wind turbine maintenance involves corrective actions that address unexpected issues arising during operation, ensuring that any failures are promptly resolved to minimize downtime. Importantly, 62.9% of all failure causes are internal engineering-related failure modes, highlighting the necessity for proactive coastal wind turbine maintenance approaches.

Implementing condition-based upkeep (CBM) strategies can significantly enhance efficiency in coastal wind turbine maintenance. By utilizing information from sensors to monitor the condition of machinery components in real-time, operators can enhance coastal wind turbine maintenance by detecting potential problems before they escalate into significant failures. Regular coastal wind turbine maintenance typically involves upkeep every six months to one year, depending on design and operating conditions, which is vital for maintaining optimal performance. For example, a wind farm in Europe that adopted a CBM strategy reported a 15% decrease in upkeep expenses and a 10% improvement in turbine availability. This case illustrates the effectiveness of thorough upkeep activities, such as coastal wind turbine maintenance, in optimizing operational performance and reducing overall expenses in wind energy projects. Moreover, inadequate upkeep can lead to unplanned service, emphasizing the importance of coastal wind turbine maintenance to avoid failure in meeting peak electricity demand and lost income for providers. Furthermore, failure rates increase with the power output of the plant, making coastal wind turbine maintenance essential for personnel to develop customized upkeep plans.

Leverage Data-Driven Maintenance Strategies

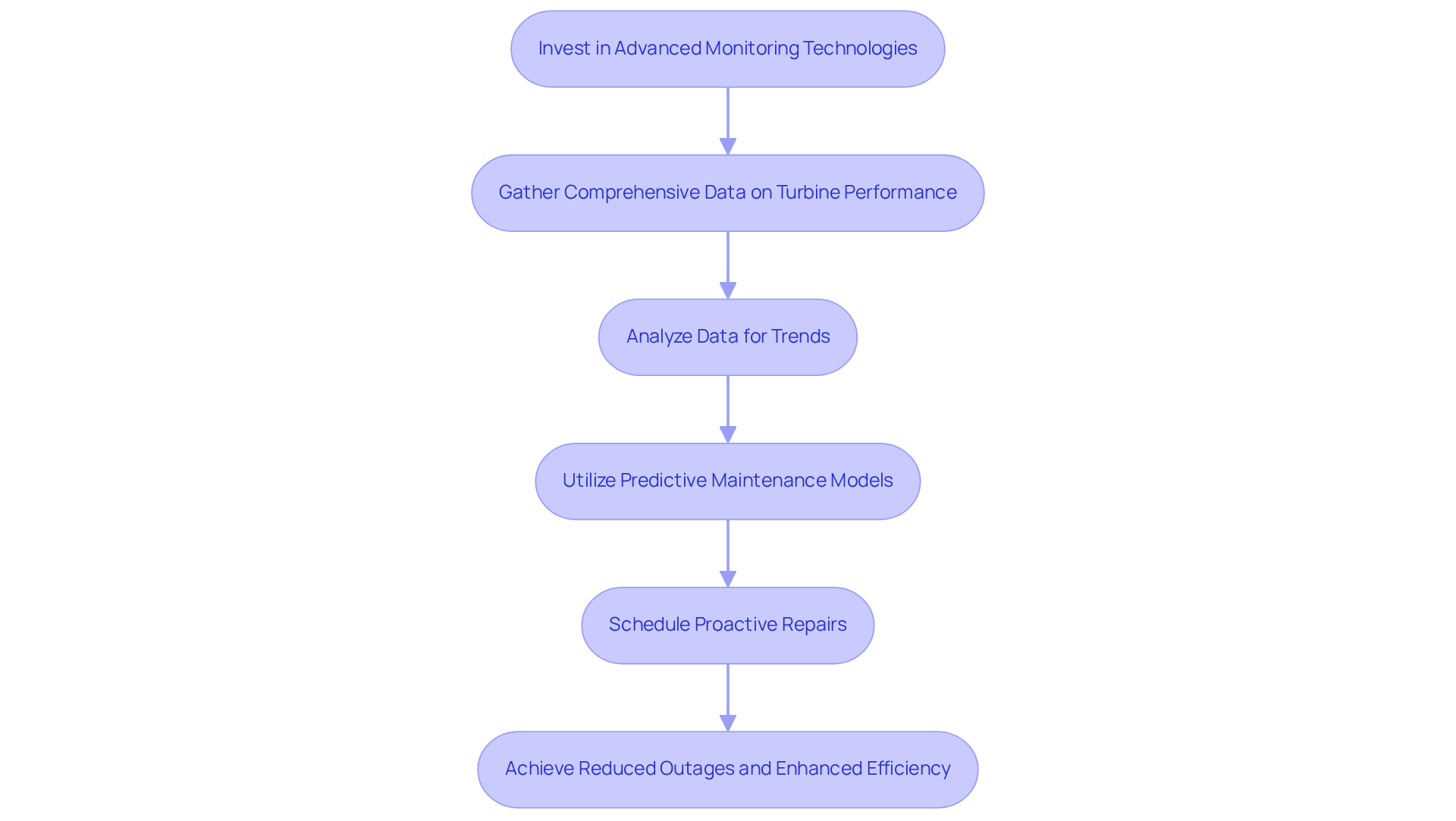

To effectively implement data-driven upkeep strategies, operators must invest in advanced monitoring technologies that gather comprehensive data on turbine performance and environmental conditions, including weather forecasts. This information can be thoroughly examined to reveal trends and forecast upkeep requirements. For instance, predictive upkeep models utilize historical data to anticipate potential component failures, enabling proactive scheduling of repair tasks. Notably, predictive upkeep has the potential to reduce outages by up to 30%, significantly enhancing operational efficiency.

A notable case study from a prominent offshore wind farm demonstrated that adopting a data-driven upkeep strategy resulted in a remarkable 25% reduction in unplanned downtime, alongside a significant boost in overall energy production. This outcome underscores the transformative impact of leveraging data to enhance upkeep approaches and improve operational efficiency. As emphasized by industry leaders, investing in high-quality sensors and monitoring equipment is crucial for the successful implementation of these strategies. Furthermore, operators should remain vigilant regarding common pitfalls in data-driven upkeep, such as over-reliance on technology without adequate workforce training, to ensure effective application.

Adopt Specialized Techniques for Offshore Maintenance

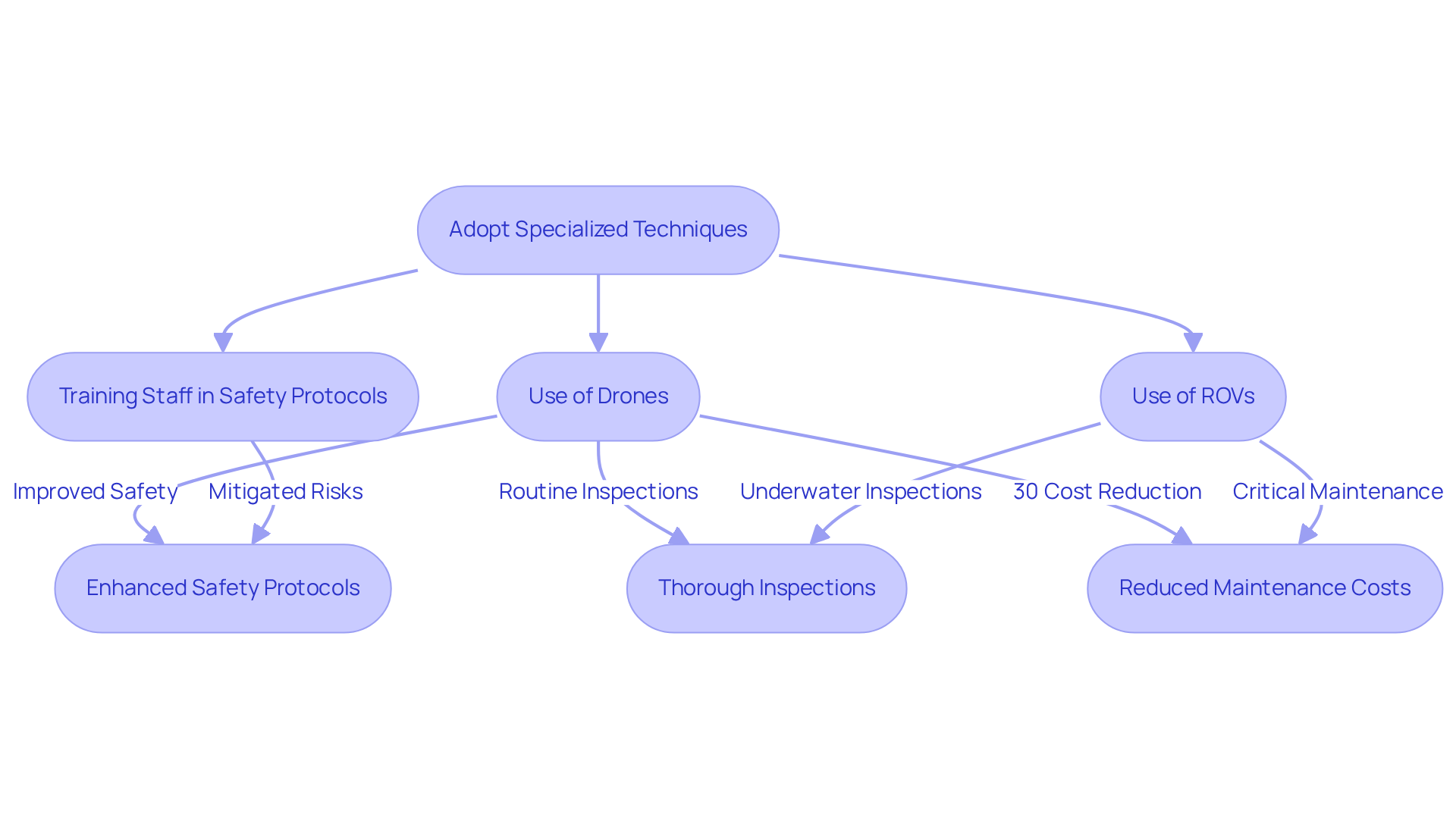

Specialized methods for offshore upkeep are revolutionizing the industry, particularly through the use of drones for inspections. These drones can safely evaluate rotor conditions without the need for personnel to ascend the structures, significantly enhancing safety protocols. Furthermore, the employment of remotely operated vehicles (ROVs) facilitates thorough underwater inspections of turbine foundations and mooring systems, addressing critical maintenance needs.

Training staff in safety protocols specific to offshore environments is vital. This training helps to mitigate risks associated with harsh weather and challenging sea conditions, ensuring a safer operational framework.

Consider a recent offshore wind project in the North Sea, which effectively utilized drones for routine inspections. This initiative led to a remarkable 30% reduction in maintenance costs and improved safety outcomes, underscoring the effectiveness of specialized offshore maintenance techniques. Such results not only demonstrate the tangible benefits of these methods but also highlight the necessity of adopting advanced technologies in offshore operations.

Conclusion

Establishing effective maintenance strategies for coastal wind turbines is vital for optimizing performance and ensuring long-term reliability. Implementing structured protocols that encompass regular inspections, comprehensive upkeep activities, data-driven approaches, and specialized techniques for offshore maintenance allows operators to significantly enhance operational efficiency while minimizing costs and downtime.

Key insights from this article underscore the necessity of:

- A thorough maintenance schedule

- The integration of predictive maintenance strategies

- The leveraging of advanced monitoring technologies

Successful case studies illustrate the tangible benefits of these practices, including improved operational efficiency and reduced maintenance costs. Furthermore, the adoption of specialized techniques, such as drone inspections and condition-based maintenance, highlights the industry's shift towards innovative solutions that prioritize safety and effectiveness.

As the demand for renewable energy escalates, the significance of robust coastal wind turbine maintenance strategies becomes increasingly critical. Operators are urged to adopt these best practices not only to enhance their maintenance protocols but also to contribute to the overall sustainability and reliability of wind energy systems. Investing in these strategies today will pave the way for a more efficient and resilient future in wind energy production.

Frequently Asked Questions

What is the importance of establishing regular maintenance protocols for wind turbines?

Establishing regular maintenance protocols is crucial for ensuring the efficiency, performance, and reliability of wind turbines. It helps in identifying issues early, reducing unscheduled repairs, and enhancing operational efficiency.

What does the daily maintenance check for wind turbines involve?

Daily maintenance checks involve visual assessments of the turbine's exterior, including inspections of the blades and nacelle to promptly identify any immediate issues.

What are the components of monthly maintenance for wind turbines?

Monthly maintenance includes more detailed inspections such as verifying lubrication levels and assessing electrical systems to ensure everything is functioning correctly.

What is required during the annual maintenance of wind turbines?

Annual maintenance requires comprehensive assessments of all mechanical parts, including gearboxes and generators, which should be performed by certified technicians.

How do checklists contribute to wind turbine maintenance?

Utilizing checklists ensures that all necessary tasks are completed systematically, minimizing the risk of oversight during maintenance procedures.

What are predictive upkeep strategies and how do they benefit wind turbine maintenance?

Predictive upkeep strategies involve ongoing observation of each generator, allowing for preventive actions before problems escalate. This approach enhances efficiency and reduces costs associated with unscheduled repairs.

How does remote control technology impact wind turbine maintenance?

The incorporation of remote control technologies enables centralized oversight and management of generators, enhancing operational efficiency and decreasing the need for on-site visits, which is particularly beneficial for upkeep in remote areas.

Can you provide an example of the benefits of regular maintenance protocols?

An example is a wind farm in Texas that implemented a strict upkeep schedule, resulting in a 20% rise in operational efficiency over two years, demonstrating the advantages of adopting regular maintenance protocols.

What common pitfalls should operators avoid in wind turbine maintenance?

Operators should avoid unnecessary servicing and incidental damage, which can hinder repair strategies and lead to increased downtime.

List of Sources

- Establish Regular Maintenance Protocols for Wind Turbines

- Wind Farm Maintenance Planning (https://firetrace.com/fire-protection-blog/wind-farm-maintenance)

- Innovative Wind Turbine Maintenance | Efficiency in 2025 (https://ast-networks.com/insights/blog/predictive-wind-turbine-maintenance)

- O&M Best Practice Issue Discussion: Maintenance Approaches (https://pnnl.gov/projects/om-best-practices/maintenance-approaches)

- 'I know windmills very much': Trump's top 10 wind power quotes (https://rechargenews.com/wind/i-know-windmills-very-much-trumps-top-10-wind-power-quotes/2-1-729724)

- National Wind Watch | Quotations (https://wind-watch.org/quotes.php)

- Implement Comprehensive Maintenance Activities

- Wind Turbine Maintenance: Components, Strategies, and Tools - Enerpac Blog (https://blog.enerpac.com/wind-turbine-maintenance-components-strategies-and-tools)

- Thermax’s ROSS simplifies machine monitoring and corrective maintenance at Adam Afrique - Thermax | Trusted Partner in Energy Transition (https://thermaxglobal.com/case_studies/thermaxs-ross-simplifies-machine-monitoring-and-corrective-maintenance-at-adam-afrique)

- Wind Farm Corrective Maintenance Strategies - SBL Solutions (https://sblsolutions.com.au/news/wind-farm-corrective-maintenance-strategies)

- Wind Turbine Maintenance: A Complete Guide | BGB (https://bgbinnovation.com/knowledge/news-and-articles/wind-turbine-maintenance-guide)

- Leverage Data-Driven Maintenance Strategies

- AI-powered service supports offshore wind performance management (https://offshore-mag.com/renewable-energy/news/55248051/ai-powered-service-supports-offshore-wind-performance-management)

- Innovative Wind Turbine Maintenance | Efficiency in 2025 (https://ast-networks.com/insights/blog/predictive-wind-turbine-maintenance)

- Why AI and energy are the new power couple – Analysis - IEA (https://iea.org/commentaries/why-ai-and-energy-are-the-new-power-couple)

- Wind farm repowering should be data-driven (https://renewableenergyworld.com/wind-power/wind-farm-repowering-should-be-data-driven)

- Adopt Specialized Techniques for Offshore Maintenance

- OEG inks three-year contract for Ørsted’s six German offshore wind farms (https://offshore-mag.com/renewable-energy/news/55280090/oeg-energy-group-oeg-inks-three-year-contract-for-rsteds-six-german-offshore-wind-farms)