Overview

This article addresses the critical challenge of long-term battery sustainability solutions for electric vehicle (EV) development. It highlights a range of innovative technologies, including:

- Sodium-ion batteries

- Solid-state batteries

- Battery recycling

- Responsible sourcing practices

These advancements collectively aim to mitigate environmental impacts and enhance the sustainability of battery production and usage within the EV sector.

Introduction

The electric vehicle (EV) industry stands at a pivotal moment, where the demand for sustainable solutions is fundamentally reshaping the landscape of battery technology. As the world confronts the environmental impacts of traditional energy sources, innovative strategies for long-term battery sustainability are emerging, poised to revolutionize the methods of energy storage and utilization.

However, with a multitude of options and technologies available, how can stakeholders effectively navigate the complexities of battery sustainability to secure a greener future for electric mobility? This article delves into seven groundbreaking solutions that not only enhance the efficiency and safety of battery systems but also align with the pressing need for sustainable practices in the EV sector.

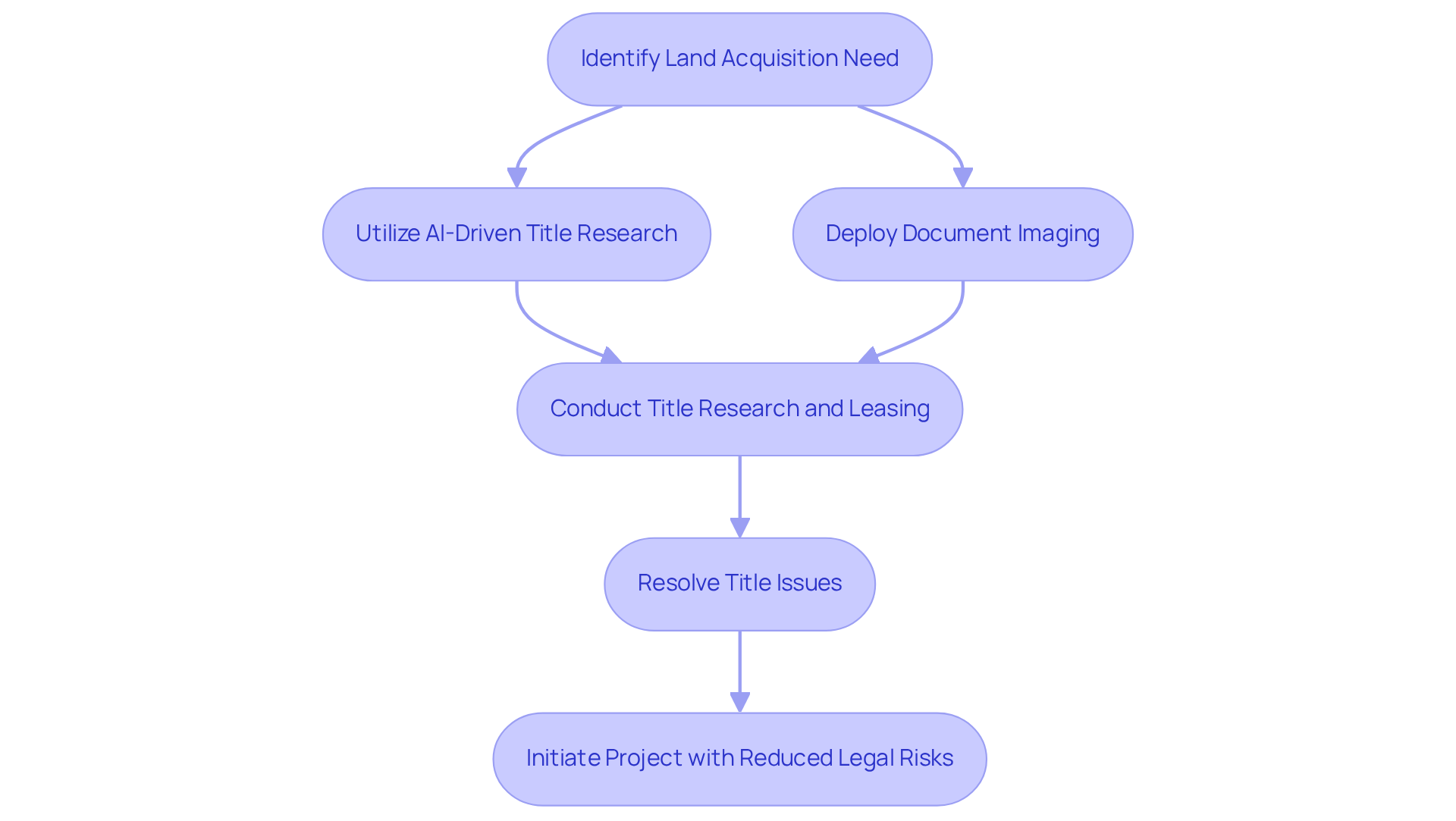

Harbinger Land | Advanced Title Research Solutions for Sustainable Land Acquisition

Harbinger Land addresses the complexities of land acquisition in the electric vehicle (EV) sector by utilizing advanced AI-driven title research solutions alongside effective document imaging. The challenges of navigating legal and regulatory hurdles in this process are significant. By digitizing property data, Harbinger Land empowers title agents to conduct title research and leasing efficiently and cost-effectively. This innovative software swiftly resolves title issues, facilitating quicker project initiation and minimizing the risk of legal complications.

Moreover, by deploying imaging agents to courthouses or acquiring documents through records requests, Harbinger Land can rapidly obtain extensive datasets as required. This streamlined approach not only enhances operational efficiency but also aligns with the long-term battery sustainability solutions of EV initiatives. The integration of advanced technology in title research ensures responsible land acquisition, adhering to environmental regulations and supporting long-term battery sustainability solutions in the development of EV infrastructure.

Successful case studies illustrate the effectiveness of this approach, showcasing how AI-driven solutions and efficient document imaging can transform land acquisition into a more efficient and sustainable endeavor. Are you ready to revolutionize your land acquisition process? Harbinger Land stands ready to assist you in navigating these challenges with confidence and expertise.

Sodium-Ion Batteries: A Sustainable Alternative to Lithium-Ion

Sodium-ion cells emerge as a sustainable alternative to conventional lithium-ion cells, leveraging abundant materials that significantly reduce the environmental impact tied to lithium extraction. Recent advancements demonstrate that sodium-ion cells can achieve a storage capacity of up to 247 watt-hours per kilogram (Wh/kg) and a power output of 34,748 watts per kilogram (W/kg), showcasing their competitive performance metrics. However, it is crucial to acknowledge that sodium-ion cells currently exhibit lower energy density compared to lithium-ion cells, which limits their driving range. Preliminary assessments indicate that these power sources can endure over 5,000 charging cycles without significant deterioration, positioning them as a viable option for electric vehicles (EVs), albeit not a complete substitute for lithium-ion cells in high-performance applications.

Successful implementations of sodium-ion technology are already in progress, with companies like CATL launching sodium-ion power sources for smaller electric vehicles, such as e-bikes and scooters. This transition not only addresses the growing demand for long-term battery sustainability solutions but also highlights the potential for sodium-ion cells to cater to niche markets where reduced power density is acceptable.

Researchers emphasize the ecological benefits of sodium-ion technology, noting that its manufacturing currently emits more greenhouse gases compared to lithium-ion systems, despite certain performance challenges. As the technology evolves, ongoing research aims to enhance storage capacity and overall efficiency, further solidifying sodium-ion cells' role in the future of sustainable power storage within the EV sector. The increasing focus on sustainability in power storage technology emphasizes the importance of diversifying storage options as long-term battery sustainability solutions to reduce reliance on fossil fuels and combat climate change.

Solid-State Batteries: Enhancing Safety and Efficiency in EVs

Solid-state cells signify a transformative leap in energy storage technology, markedly enhancing safety and efficiency compared to conventional lithium-ion units. By substituting the liquid electrolyte with a solid electrolyte, these energy storage systems mitigate fire hazards and elevate energy density, with forecasts indicating they could achieve energy densities 2-2.5 times greater than existing lithium-ion alternatives. This innovation not only boosts the performance of powered transportation but also contributes to long-term battery sustainability solutions by extending energy storage lifespan and minimizing waste.

As manufacturers increasingly invest in solid-state technology, the prospect of safer, more efficient vehicles becomes increasingly tangible. Industry specialists underscore that advancements in solid-state technology are essential for the future of electric mobility, with one expert asserting, 'Innovation is not optional; it's vital for survival' in the competitive energy storage landscape.

EnZinc further highlights the potential to reduce EV energy storage costs by over 50% and enhance rechargeability, advocating strongly for solid-state technology. Successful implementations in EV manufacturing, such as Nio's semi-solid-state energy storage systems achieving a range of 650 miles on a single charge, illustrate the potential of this technology to revolutionize the market and bolster consumer confidence.

Moreover, solid-state energy storage systems may achieve a full charge in under 10 minutes, significantly improving charging efficiency. The automotive sector is poised to redefine safety standards and operational efficiency in electric vehicles through long-term battery sustainability solutions with solid-state energy storage systems.

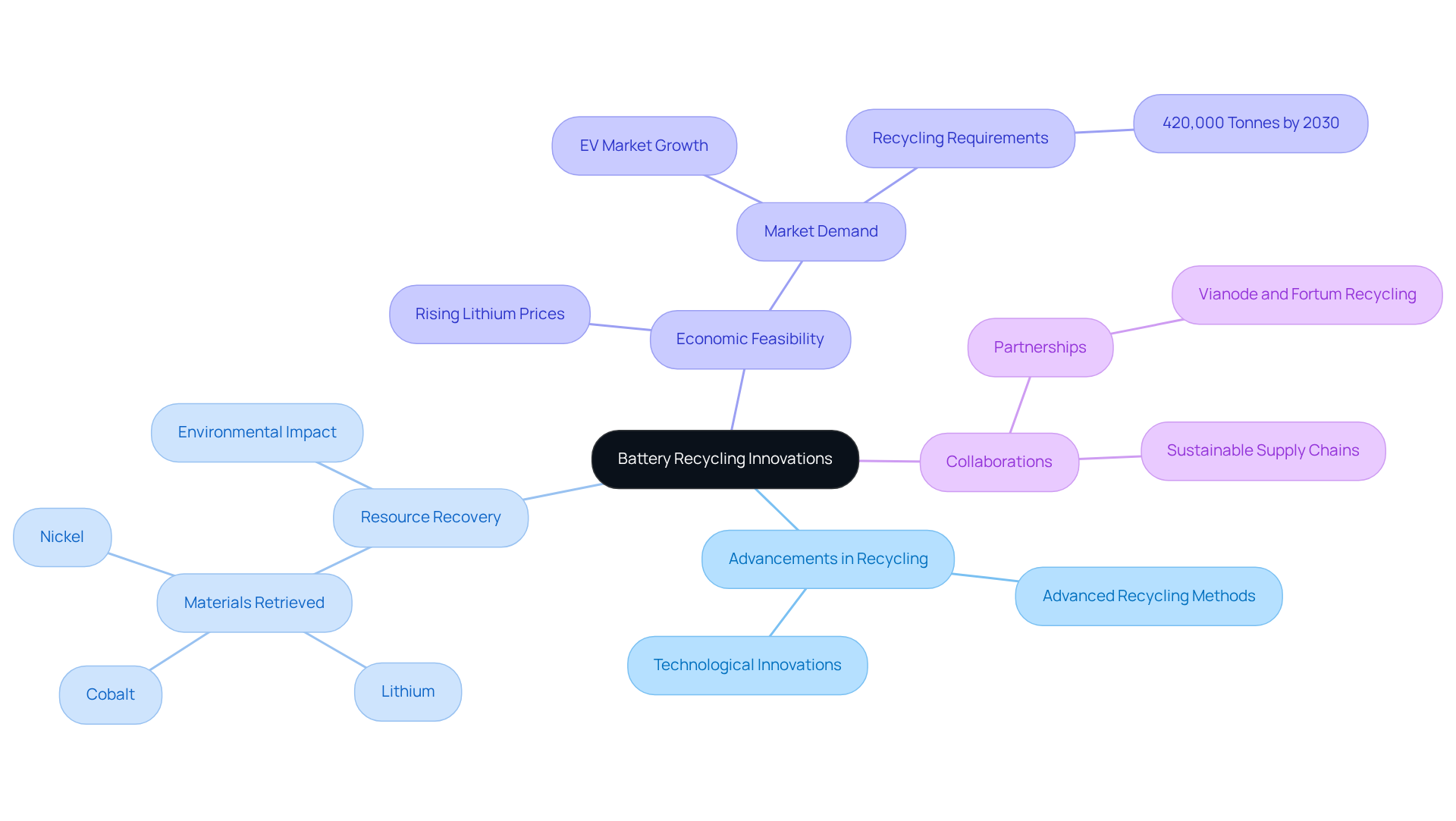

Battery Recycling Innovations: Paving the Way for a Closed-Loop System

Advancements in energy storage recycling are crucial for establishing long-term battery sustainability solutions that contribute to a closed-loop system, reducing waste and enhancing resource recovery. Advanced recycling methods can efficiently retrieve valuable materials such as lithium, cobalt, and nickel from used power sources, enabling these resources to be repurposed in new energy cell production. This process mitigates the demand for virgin materials and significantly reduces the environmental impact associated with mining.

With the electric vehicle (EV) market expected to grow swiftly, implementing long-term battery sustainability solutions through efficient recycling methods is essential for guaranteeing the sustainability of energy cell production and utilization. As emphasized by industry leaders, the economic feasibility of recycling is becoming increasingly vital. For instance, Europe will require approximately 420,000 tonnes of EV cell recycling by 2030 to meet rising demands.

By adopting closed-loop systems, the industry can enhance long-term battery sustainability solutions while also addressing the economic challenges posed by rising lithium prices. As Lilian Schwich, co-founder and CEO, states, "We need to change our mindset in general. We need to change our habits." This cultural shift is crucial for the effective implementation of recycling practices.

Moreover, collaborations, such as that between Vianode and Fortum Recycling, illustrate the joint efforts necessary to establish sustainable supply chains for electric vehicles. These partnerships are vital in paving the way for long-term battery sustainability solutions within the realms of energy storage and recycling.

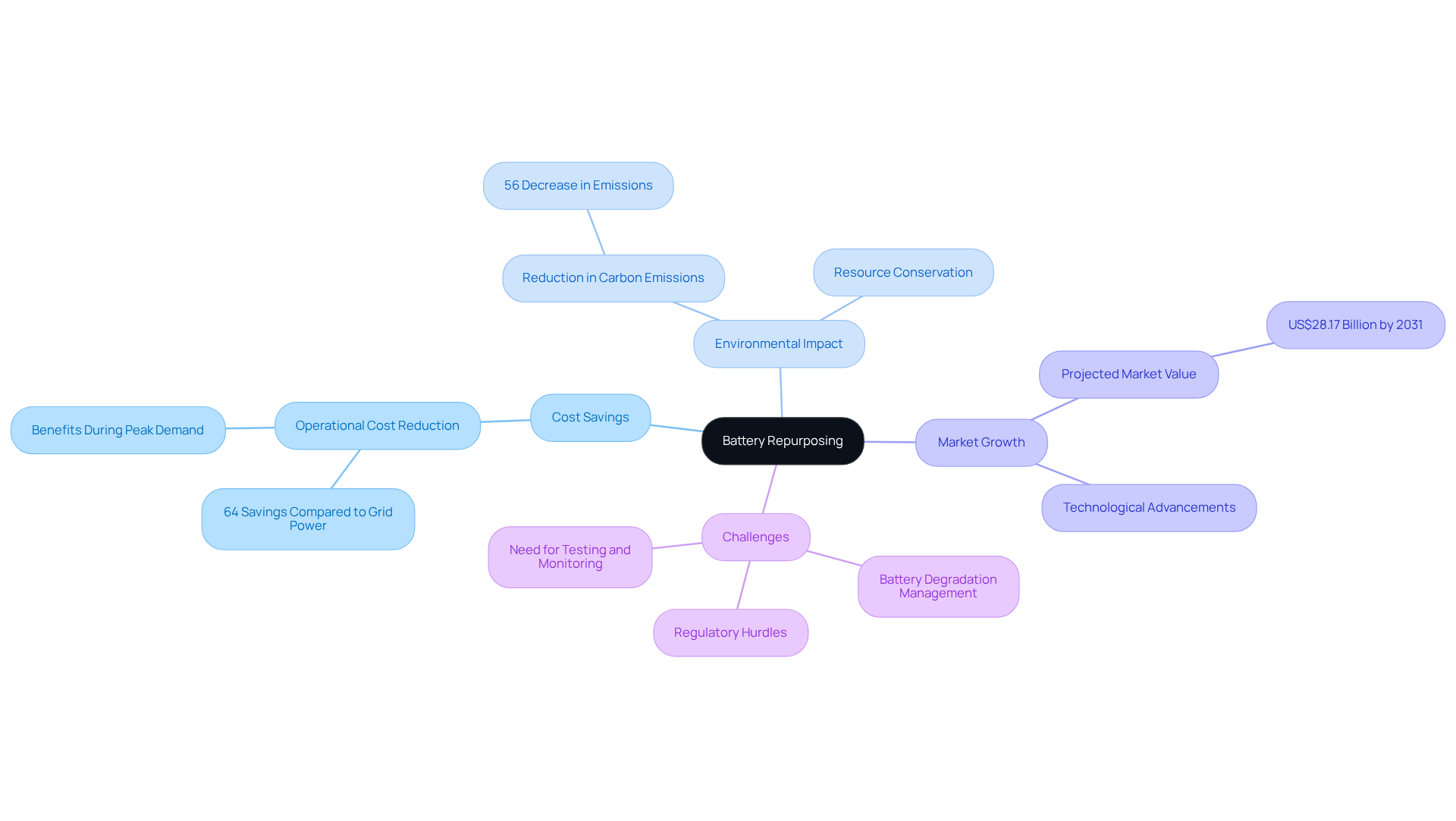

Battery Repurposing: Extending Lifespan Beyond Electric Vehicles

Repurposing cells represents a critical strategy for extending the lifespan of used EV power sources and minimizing waste. When power sources reach their end-of-life in vehicles, they can be transformed into stationary power storage systems, providing backup electricity for homes and businesses. This approach not only increases the utility of these power sources but also facilitates the integration of renewable resources by storing excess energy generated from solar and wind.

Research indicates that employing second-life power sources can yield operational cost savings of up to 64% compared to grid power, along with significant reductions in carbon emissions, potentially decreasing by as much as 56%. Experts emphasize that repurposing cells previously utilized in EVs provides long-term battery sustainability solutions for meeting power demands during peak periods.

With the market for refurbished energy cells projected to reach US$28.17 billion by 2031, driven by growing investments and technological advancements, the EV sector is poised to enhance its long-term battery sustainability solutions considerably. Robert Brandt notes that reusing power cells during peak demand is essential for improving energy management.

Nevertheless, addressing the challenges related to power source degradation is crucial, necessitating thorough testing and monitoring to fully realize the benefits of repurposing. Given the forecast of 3.4 million discarded EV power sources by 2025, the need for effective repurposing strategies is evident.

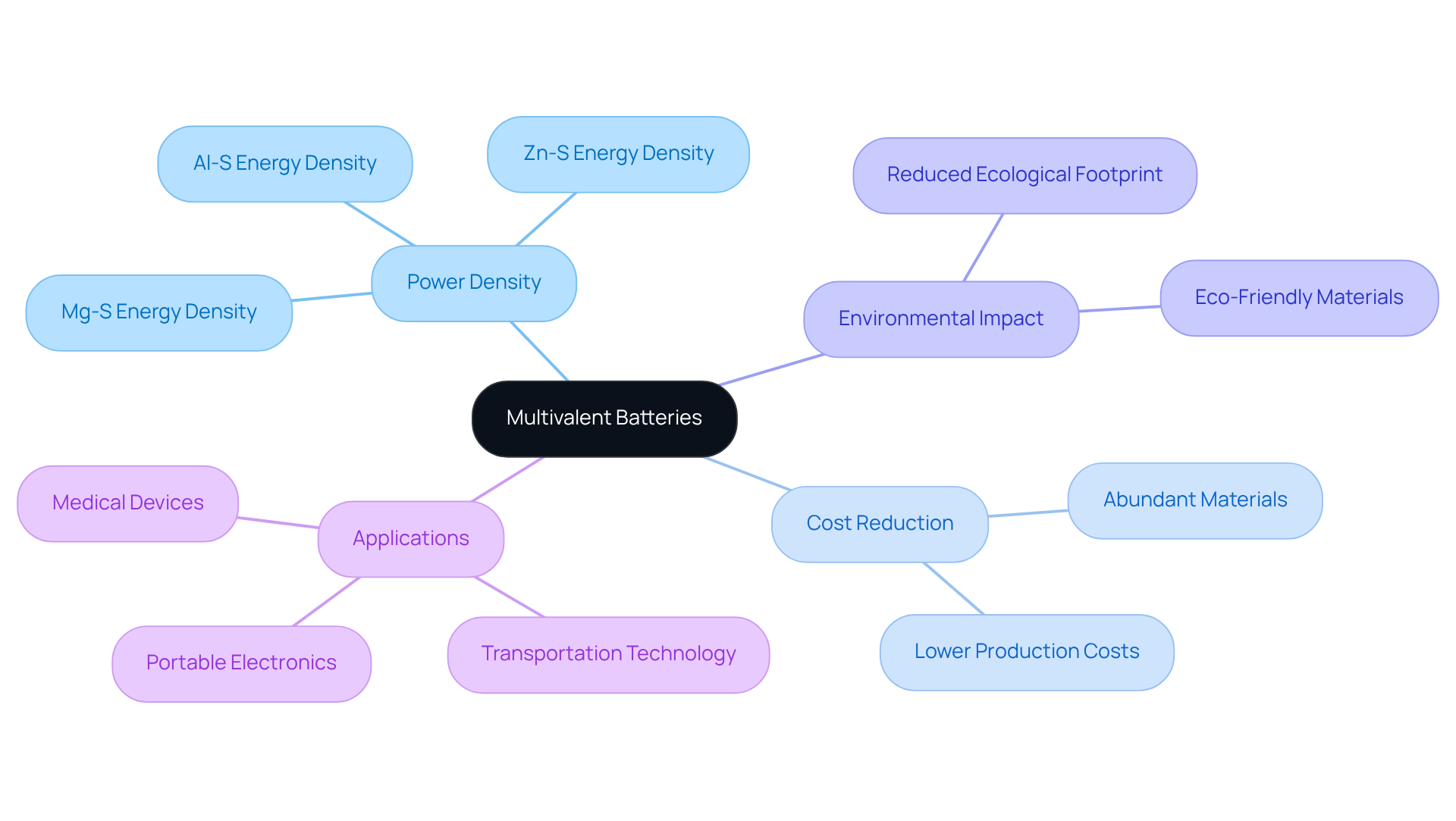

Multivalent Batteries: A New Frontier in Sustainable Energy Storage

Multivalent cells represent a significant advancement in sustainable power storage, utilizing various valence states of metals such as magnesium and aluminum. These cells promise greater power densities and reduced costs compared to traditional lithium-ion cells. Notably, the volumetric energy density of magnesium-sulfur (Mg-S) cells reaches an impressive 3221 Wh L⁻¹, underscoring their potential for high-performance applications. Furthermore, the materials used in multivalent cells are not only more abundant but also environmentally friendly, substantially reducing the ecological impact associated with cell production.

Researchers assert that multivalent metal-ion cells could serve as viable alternatives to lithium-based systems, particularly in transportation technology, where cost and resource availability are paramount. Successful implementations of multivalent energy storage technology in automobiles have demonstrated their efficiency, paving the way for broader acceptance. As research advances, multivalent power sources are expected to play a crucial role in the evolution of e-mobility and the development of long-term battery sustainability solutions, aligning with the growing demand for eco-friendly technologies.

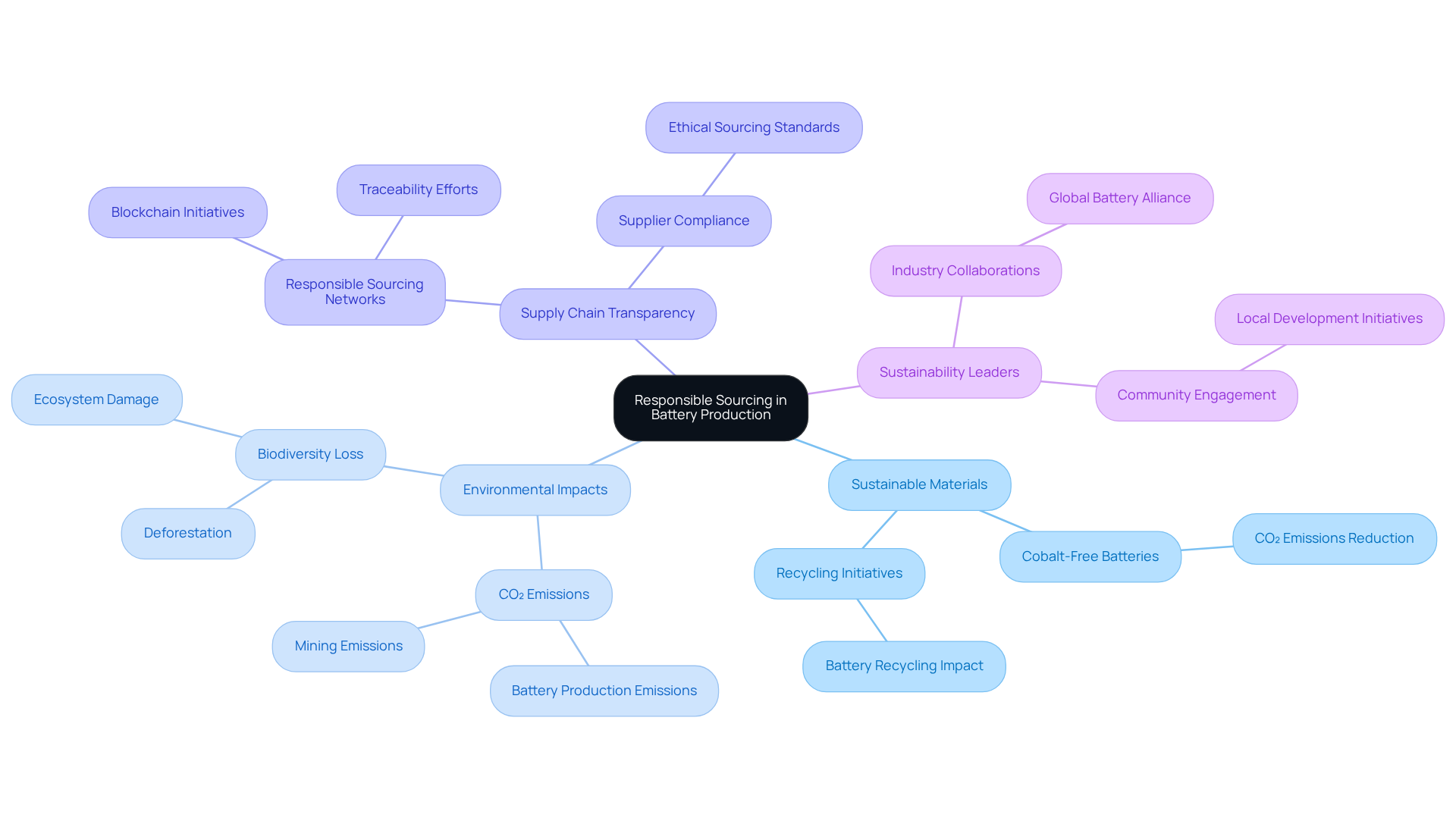

Responsible Sourcing: Addressing Environmental Impacts in Battery Production

Responsible sourcing of materials for power cell production is imperative for mitigating environmental impacts. This process entails sourcing raw materials from sustainable origins and ensuring compliance with environmental regulations in mining practices. The electric vehicle (EV) industry must prioritize transparency within its supply chains, collaborating with suppliers who are committed to sustainable practices.

Mining operations, particularly for cobalt and nickel, have been linked to significant ecological damage, including deforestation and biodiversity loss. For instance, extracting materials for energy storage contributes approximately 15% of overall battery-related CO₂ emissions due to energy-intensive extraction methods. By implementing responsible sourcing strategies, companies can not only reduce these impacts but also enhance their overall sustainability and significantly decrease the carbon footprint associated with energy storage production, which is essential for developing long-term battery sustainability solutions, generating between 40 and 60 kilograms of CO₂ emissions per kilowatt-hour of capacity.

Leaders in sustainability, such as Benedikt Sobotka, assert that a commitment to ethical sourcing can foster a more resilient supply chain, ultimately benefiting both the environment and local communities. Effective methods in sustainable material procurement, such as the establishment of the Responsible Sourcing Blockchain Network, which monitors cobalt from mine to producer, are paving the way for improved accountability and traceability in the power storage supply chain. This guarantees that the transition to renewable mobility is both environmentally and socially responsible.

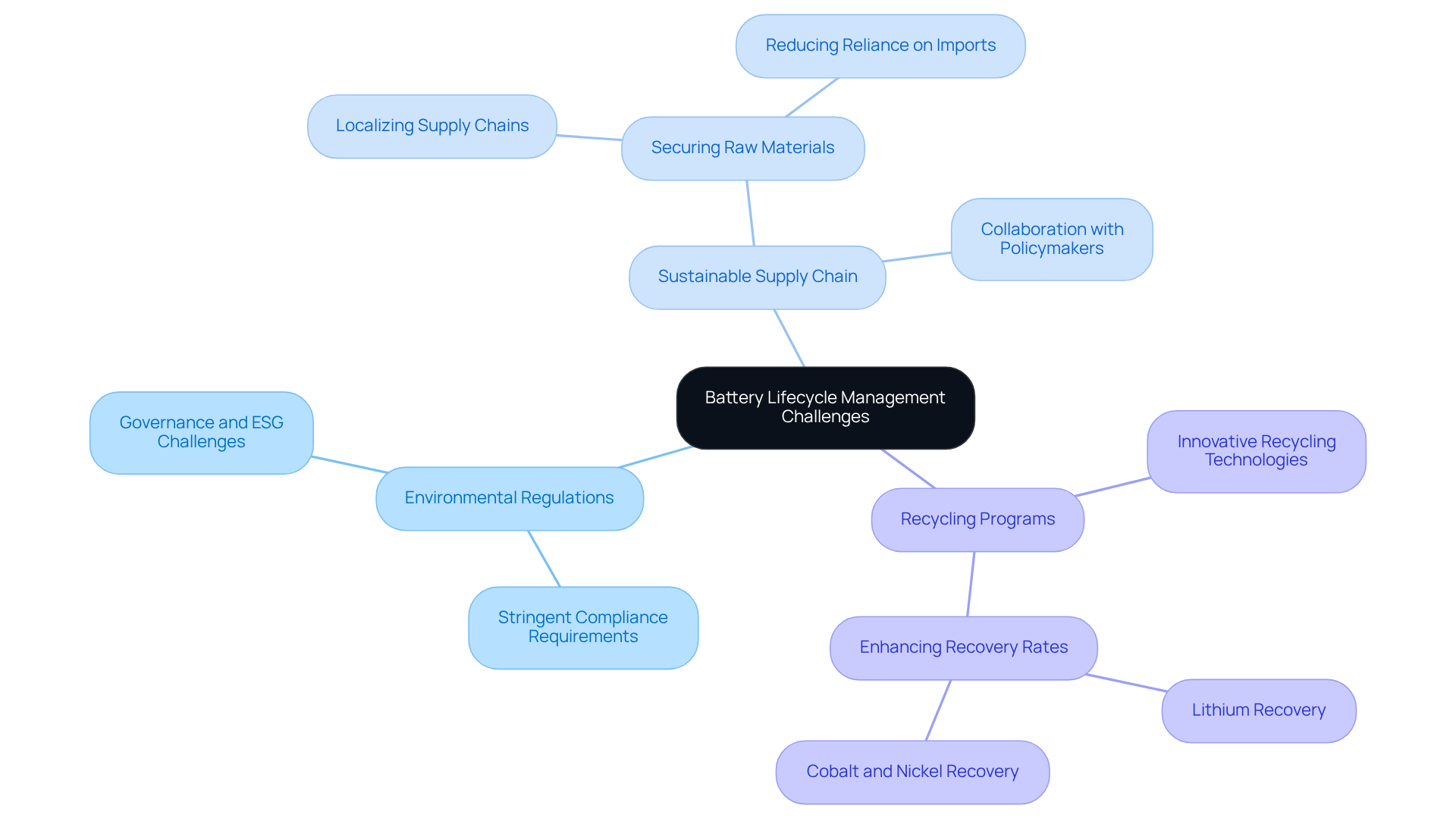

Challenges in Battery Lifecycle Management for OEMs: Navigating Sustainability

Original Equipment Manufacturers (OEMs) encounter significant challenges in managing the entire lifecycle of energy storage devices, spanning from production to disposal. The primary issues include:

- Adhering to stringent environmental regulations

- Securing a sustainable supply chain for essential raw materials

- Implementing effective recycling programs

With the demand for electric vehicles (EVs) on the rise—over 26 million EVs on the road by the end of 2022—OEMs face mounting pressure to adopt sustainable practices. To effectively navigate these complexities, a strategic approach that prioritizes long-term battery sustainability solutions at each phase of the energy storage lifecycle is crucial.

Investing in innovative recycling technologies is essential to enhance recovery rates of valuable materials such as lithium, cobalt, and nickel, which are projected to experience demand increases of 26 times and 6 times, respectively, by 2050. Furthermore, collaboration with policymakers and recyclers is vital for addressing challenges and improving efficiency throughout the battery value chain. Industry experts assert that establishing domestic supply chains and developing local recycling capabilities are critical for reducing reliance on international suppliers and minimizing environmental impacts.

Dr. John Warner, Chief Customer Officer at American Battery Solutions, emphasizes that success in the energy storage sector hinges on collaboration across the entire ecosystem. By confronting these challenges head-on, OEMs can play a pivotal role in fostering long-term battery sustainability solutions for a more sustainable future in electric transport and energy storage.

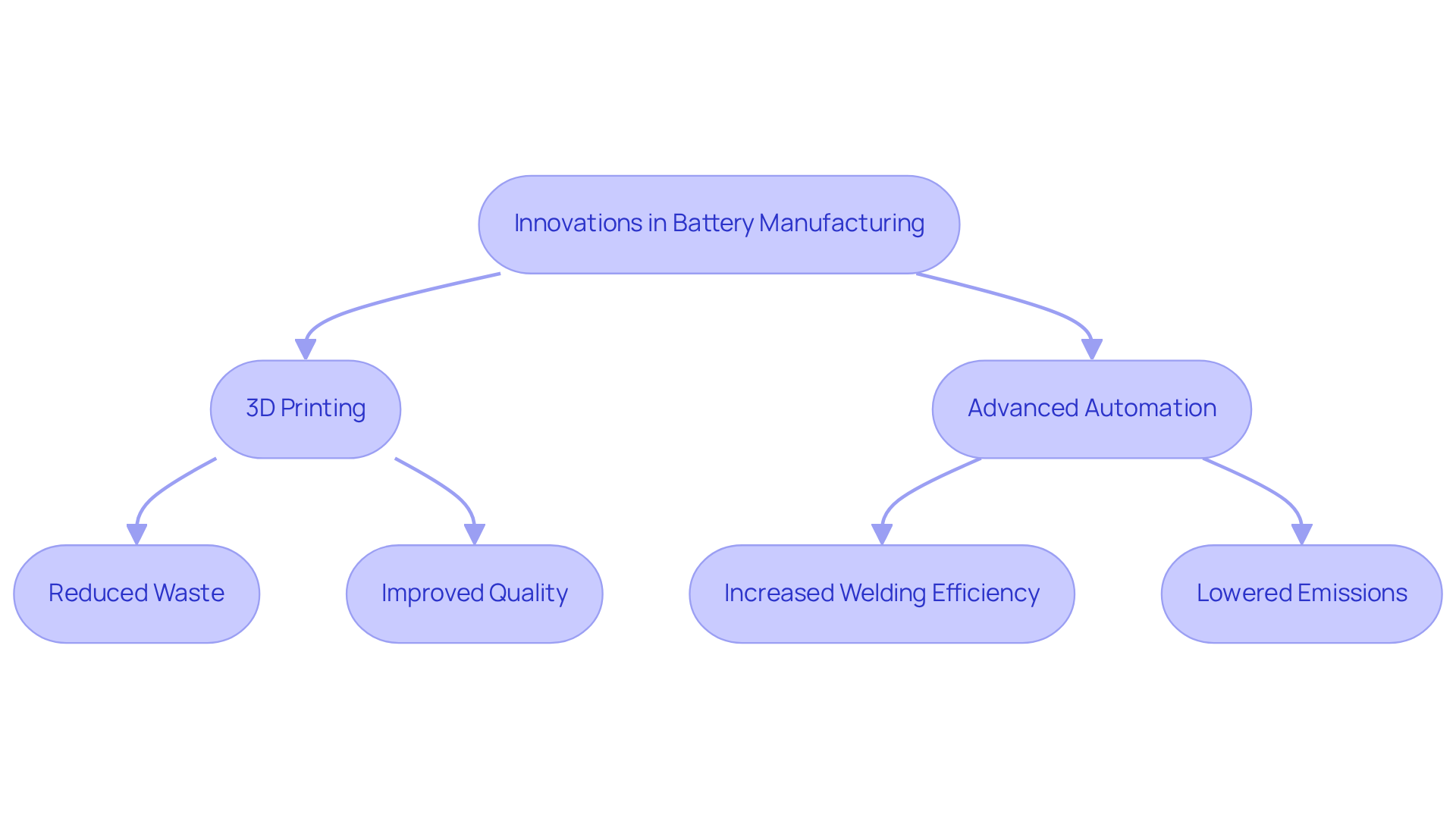

Innovations in Battery Manufacturing: Driving Sustainable Practices

Advancements in energy storage manufacturing processes are crucial for fostering sustainability within the industry. Techniques such as 3D printing present significant potential, with successful implementations leading to enhanced production efficiency and notable waste reduction. Contemporary power cell assemblies, for instance, often necessitate over 10,000 laser welds; even a single defect can diminish vehicle range by nearly 2%. By leveraging 3D printing, manufacturers can streamline these processes, thereby minimizing waste and improving overall quality.

In addition, the integration of advanced automation technologies has been shown to optimize production efficiency. Companies have reported improvements of up to 30% in welding efficiency. A case in point is ATS Industrial Automation, which achieved a 30% increase in welding efficiency for an automotive manufacturer, exemplifying a successful application of these technologies. With the demand for lithium-ion cells projected to surge by 500% by 2050, it is critical to recognize that nearly half of an electric vehicle’s total emissions stem from cell production. This underscores the urgency of adopting long-term battery sustainability solutions within the energy storage system manufacturing sector.

Manufacturing leaders assert that embracing these technological advancements not only bolsters operational sustainability but also promotes long-term battery sustainability solutions that align with the broader goals of the electric vehicle industry. Transitioning to renewable energy sources could potentially conserve over 100 million metric tons of CO2 annually, significantly reducing the carbon footprint associated with energy storage production. By prioritizing innovations such as 3D printing and automation, manufacturers can effectively contribute to a more sustainable future while addressing the escalating demands of the market.

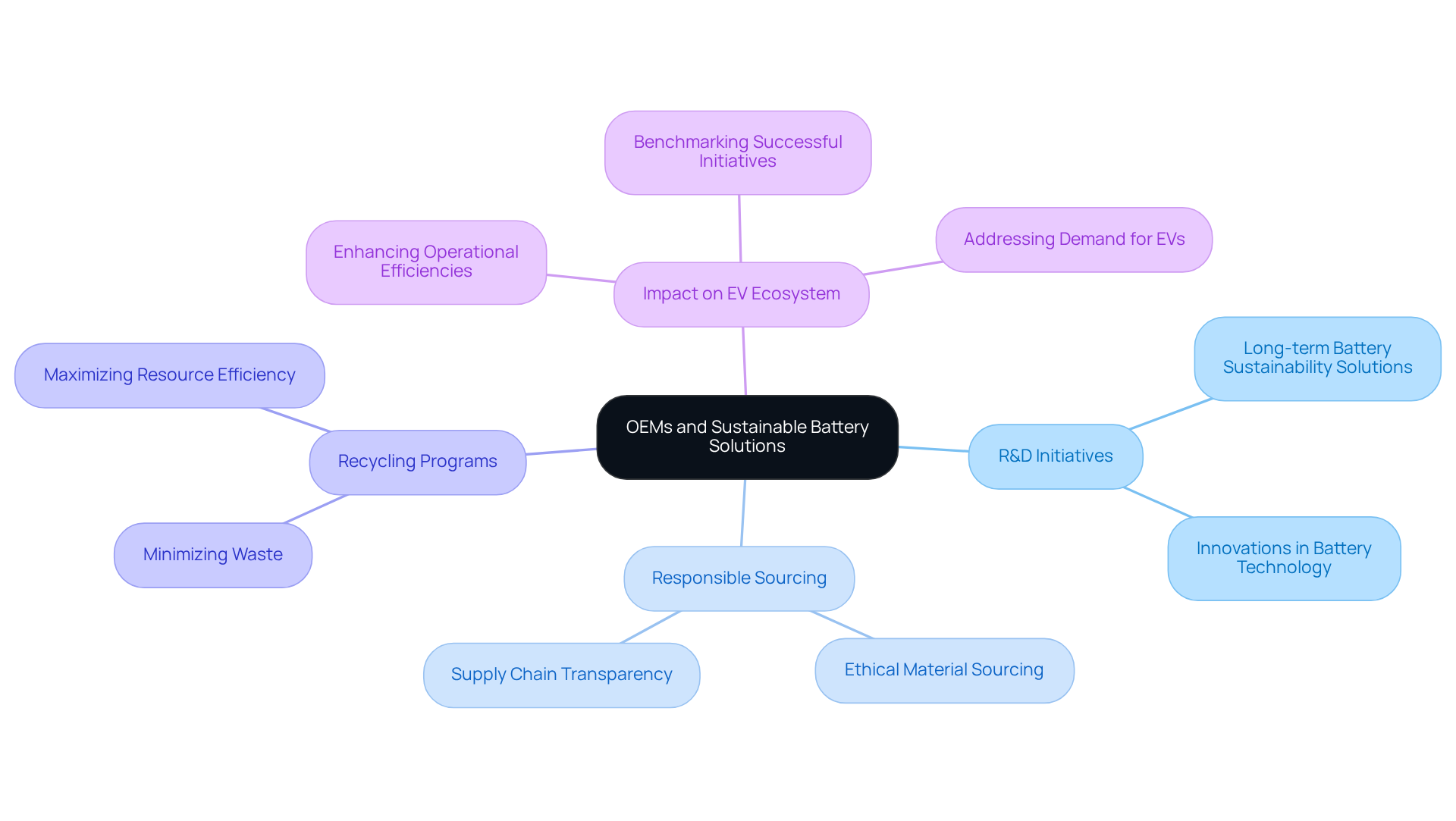

Future Outlook: The Role of OEMs in Shaping Sustainable Battery Solutions

The trajectory of sustainable energy storage solutions is significantly influenced by the initiatives and innovations led by Original Equipment Manufacturers (OEMs). As the automotive market rapidly expands, it becomes essential for OEMs to weave sustainability into their product development and supply chain strategies. This imperative includes substantial investments in research and development aimed at pioneering long-term battery sustainability solutions, embracing responsible sourcing practices, and bolstering recycling programs.

Notably, statistics reveal that OEMs are increasingly engaging in recycling initiatives, which are crucial for minimizing waste and maximizing resource efficiency within the electric vehicle (EV) industry. By taking a proactive stance on sustainability, OEMs not only enhance their operational efficiencies but also position themselves as frontrunners in fostering a more environmentally friendly future for battery-powered transportation.

Industry analysts emphasize that innovations stemming from OEMs can profoundly affect the overall sustainability of the EV ecosystem, highlighting the critical need for ongoing R&D efforts to cultivate long-term battery sustainability solutions. Successful sustainability initiatives from various OEMs serve as benchmarks, illustrating the potential for significant environmental benefits while simultaneously addressing the surging demand for electric vehicles.

Conclusion

The future of electric vehicles (EVs) is fundamentally tied to the implementation of long-term battery sustainability solutions that tackle both environmental concerns and the escalating demand for efficient energy storage. Innovative technologies such as sodium-ion and solid-state batteries, alongside advancements in recycling and responsible sourcing, present opportunities for the industry to significantly diminish its ecological footprint while simultaneously enhancing performance and safety. The integration of these solutions is crucial for establishing a sustainable ecosystem that facilitates the transition to cleaner transportation.

In this article, we have explored various strategies, including:

- The potential of sodium-ion batteries as a viable alternative to lithium-ion

- The transformative capabilities of solid-state technology

- The critical importance of battery recycling and repurposing

Each of these approaches plays a pivotal role in ensuring that the EV sector not only meets current energy demands but also prepares for a more sustainable future. The challenges faced by original equipment manufacturers (OEMs) in managing battery lifecycles and sourcing materials responsibly further underscore the necessity for collaborative efforts across the industry.

Ultimately, the call to action is unmistakable: stakeholders within the EV landscape must embrace these innovations and practices to cultivate a more sustainable future. By prioritizing sustainability in battery technology, the industry can enhance operational efficiencies while contributing to the global fight against climate change. The path forward is rich with opportunities for growth and responsibility, and the time to act is now.

Frequently Asked Questions

What is Harbinger Land and how does it assist in land acquisition for the electric vehicle sector?

Harbinger Land provides advanced AI-driven title research solutions and effective document imaging to assist title agents in navigating the complexities of land acquisition in the electric vehicle (EV) sector. It helps streamline the title research process, making it efficient and cost-effective.

What challenges does Harbinger Land address in land acquisition?

Harbinger Land addresses significant legal and regulatory hurdles in land acquisition by digitizing property data, which empowers title agents to resolve title issues quickly and minimizes the risk of legal complications.

How does Harbinger Land enhance operational efficiency in land acquisition?

By deploying imaging agents to courthouses and acquiring documents through records requests, Harbinger Land can rapidly obtain extensive datasets. This streamlined approach improves operational efficiency and aligns with long-term sustainability solutions for EV initiatives.

What are sodium-ion batteries and how do they compare to lithium-ion batteries?

Sodium-ion batteries are a sustainable alternative to lithium-ion batteries, using abundant materials that reduce environmental impact. They currently have lower energy density compared to lithium-ion cells, which limits their driving range, but they can endure over 5,000 charging cycles without significant deterioration.

What are the potential applications of sodium-ion batteries in the electric vehicle market?

Sodium-ion technology is being implemented for smaller electric vehicles, such as e-bikes and scooters, addressing the demand for long-term battery sustainability solutions in niche markets where reduced power density is acceptable.

What are the ecological benefits and challenges of sodium-ion technology?

Sodium-ion technology has ecological benefits due to its use of abundant materials, but its manufacturing currently emits more greenhouse gases than lithium-ion systems. Ongoing research aims to enhance its storage capacity and efficiency.

What are solid-state batteries and how do they improve safety and efficiency in electric vehicles?

Solid-state batteries replace the liquid electrolyte with a solid electrolyte, enhancing safety by mitigating fire hazards and improving energy density. They are expected to achieve energy densities 2-2.5 times greater than lithium-ion batteries.

What advancements are being made in solid-state battery technology?

Manufacturers are increasingly investing in solid-state technology, which could reduce EV energy storage costs by over 50% and improve rechargeability. Successful implementations, like Nio's semi-solid-state systems, demonstrate the potential for improved range and charging efficiency.

How quickly can solid-state energy storage systems charge?

Solid-state energy storage systems may achieve a full charge in under 10 minutes, significantly improving charging efficiency for electric vehicles.

List of Sources

- Harbinger Land | Advanced Title Research Solutions for Sustainable Land Acquisition

- New Electric Vehicle Charging Grants Coming Soon (https://nlc.org/article/2023/02/23/new-electric-vehicle-charging-grants-coming-soon)

- Federal Policies to Expand Electric Vehicle Charging Infrastructure (https://congress.gov/crs-product/R47675)

- A global analysis of renewable energy project commissioning timelines (https://sciencedirect.com/science/article/pii/S030626192301927X)

- Electrification & EV News | Qmerit (https://qmerit.com/ev-news-electrification-news)

- Analysis of the Spatial Characteristics and Influencing Factors of Large-Scale Land Acquisition Projects in Southeast Asia (https://mdpi.com/2073-445X/13/9/1498)

- Sodium-Ion Batteries: A Sustainable Alternative to Lithium-Ion

- Topic: Sodium-ion battery industry worldwide (https://statista.com/topics/12685/sodium-ion-battery-industry-worldwide)

- Benchmarking the Performance of Lithium and Sodium‐Ion Batteries With Different Electrode and Electrolyte Materials | Request PDF (https://researchgate.net/publication/384975056_Benchmarking_the_Performance_of_Lithium_and_Sodium-Ion_Batteries_With_Different_Electrode_and_Electrolyte_Materials)

- Sodium as a Green Substitute for Lithium in Batteries (https://physics.aps.org/articles/v17/73?utm_source=chatgpt.com)

- Can Sodium-ion Batteries Be Used in Electric Vehicles? (https://linkedin.com/pulse/can-sodium-ion-batteries-used-electric-vehicles-neeraj-kumar-singal-rh9zc)

- A Complete Overview of Sodium-Ion Battery (https://ufinebattery.com/blog/a-comprehensive-guide-to-sodium-ion-battery)

- Solid-State Batteries: Enhancing Safety and Efficiency in EVs

- How Solid-State Batteries Will Revolutionize the Industry (https://apexmechanicalbg.com/the-future-of-electric-vehicles-how-solid-state-batteries-will-revolutionize-the-industry)

- Solid State Batteries & the Future of EV Battery Tech (https://recurrentauto.com/research/the-future-of-battery-technology)

- What are solid-state batteries, and how do they differ from current EV batteries? (https://batterypowertips.com/what-are-solid-state-batteries-and-how-do-they-differ-from-current-ev-batteries)

- Solid-State Battery Market Size & Industry Growth 2030 (https://futuredatastats.com/solid-state-battery-market?srsltid=AfmBOoocRM2v1Gllzw45x1vpmCv1z2qXnUu6UhI7Ytya5Cj4luWXaXqK)

- Battery Recycling Innovations: Paving the Way for a Closed-Loop System

- Innovative companies team up for game-changing EV battery breakthrough: 'Vital to reduce dependence' (https://finance.yahoo.com/news/innovative-companies-team-game-changing-111550514.html)

- cylib: next generation battery recycling (https://eif.org/what_we_do/equity/Case_studies/cylib-next-generation-battery-recycling.htm)

- Automotive Manufacturing Archives | Anguil Environmental Systems, Inc. (https://anguil.com/case_studies_category/automotive-manufacturing)

- Battery Repurposing: Extending Lifespan Beyond Electric Vehicles

- Old EV batteries can increase renewable power use while reducing resource demand – agency (https://cleanenergywire.org/news/old-ev-batteries-can-increase-renewable-power-use-while-reducing-resource-demand-agency)

- Repurposing Second-Life EV Batteries to Advance Sustainable Development: A Comprehensive Review (https://mdpi.com/2313-0105/10/12/452)

- Battery 2030: Resilient, sustainable, and circular (https://mckinsey.com/industries/automotive-and-assembly/our-insights/battery-2030-resilient-sustainable-and-circular)

- Repurposing EV Batteries for Storing Solar Energy (https://sciencedirect.com/science/article/pii/S2095809923003831)

- Second-life EV Batteries: Pioneering Sustainability & Growth (https://evmagazine.com/technology/second-life-ev-batteries-pioneering-sustainability-growth)

- Multivalent Batteries: A New Frontier in Sustainable Energy Storage

- A Roadmap to Better Multivalent Batteries (https://uh.edu/news-events/stories/july-2020/article07172020yao-nature-energy-batteries.php)

- The Rise of Multivalent Metal–Sulfur Batteries: Advances, Challenges, and Opportunities (https://advanced.onlinelibrary.wiley.com/doi/10.1002/adfm.202405358)

- Multivalent rechargeable batteries (https://sciencedirect.com/science/article/pii/S2405829719302478)

- Responsible Sourcing: Addressing Environmental Impacts in Battery Production

- EV Companies Hope to Have Responsible Battery Sourcing (https://governing.com/news/headlines/EV-Companies-Hope-to-Have-Responsible-Battery-Sourcing.html)

- Battery 2030: Resilient, sustainable, and circular (https://mckinsey.com/industries/automotive-and-assembly/our-insights/battery-2030-resilient-sustainable-and-circular)

- The Environmental Impact of Battery Production: Carbon Emissions and Sustainability Stats (https://patentpc.com/blog/the-environmental-impact-of-battery-production-carbon-emissions-and-sustainability-stats)

- 2040 Sustainable Battery Vision: Global Forum for Sustainable Batteries (https://law.berkeley.edu/research/clee/research/climate/transportation/2040-sustainable-battery-vision)

- Europe’s push for self-sufficient lithium battery production (https://automotivelogistics.media/battery-supply-chain/charging-up-in-europe/45348.article)

- Challenges in Battery Lifecycle Management for OEMs: Navigating Sustainability

- Sustainability challenges throughout the electric vehicle battery value chain (https://sciencedirect.com/science/article/pii/S1364032123010341)

- Electric Vehicle Battery Market Size, Share and Forecast 2032 (https://credenceresearch.com/report/electric-vehicle-battery-market)

- Why OEMs are investing in lithium-ion battery recycling (https://thebuzzevnews.com/oems-investing-lithium-ion-battery-recycling)

- The Battery Industry's Biggest Challenges and Opportunities in 2025 (https://batterytechonline.com/industry-outlook/the-battery-industry-s-biggest-challenges-and-opportunities-in-2025)

- Future Of EV Batteries: Trends In Battery Lifecycle Management | Dynamic Manufacturing (https://dynamicmanufacturinginc.com/the-future-of-electric-vehicles-key-trends-in-battery-lifecycle-management)

- Innovations in Battery Manufacturing: Driving Sustainable Practices

- ATS Helps a Leading Auto Manufacturer Redefine EV Battery Assembly (https://atsindustrialautomation.com/case_studies/ats-helps-leading-auto-manufacturer-redefine-ev-battery-assembly)

- Ilika – Professor Brian Hayden | Chemistry | University of Southampton (https://southampton.ac.uk/chemistry/business_partnership/case_studies/ilika.page)

- The Environmental Impact of Battery Production: Carbon Emissions and Sustainability Stats (https://patentpc.com/blog/the-environmental-impact-of-battery-production-carbon-emissions-and-sustainability-stats)

- 3D-printed lithium-ion battery shows green potential - The Engineer (https://theengineer.co.uk/content/news/3d-printed-lithium-ion-battery-shows-green-potential)

- Future Outlook: The Role of OEMs in Shaping Sustainable Battery Solutions

- EV Case Studies (https://avista.chooseev.com/commercial/case_studies)