Overview

To effectively implement safety plans for compressor stations, it is crucial to conduct thorough risk assessments, develop emergency response strategies, and ensure regular training and maintenance protocols.

Understanding operational risks and engaging stakeholders are essential for creating a robust safety framework. This framework enhances compliance and mitigates potential hazards in these facilities, ultimately safeguarding operations and personnel.

Introduction

In the intricate world of natural gas operations, compressor stations are the backbone of efficient gas transportation. However, they present a unique set of challenges and risks that must be addressed. Understanding these complexities is vital for ensuring safety and operational integrity. Each aspect of compressor station operations, from gas compression methods to advanced monitoring systems, carries potential hazards that require diligent attention.

As the industry evolves, the implementation of comprehensive safety plans becomes essential, guiding stakeholders in:

- Risk assessment

- Emergency response

- Regulatory compliance

This article delves into the key components necessary for cultivating a culture of safety within compressor stations, emphasizing the importance of proactive measures and stakeholder engagement to mitigate risks and enhance community relations.

Understand Compressor Station Operations and Risks

To effectively implement protection strategies for pump facilities, a thorough understanding of their functions and inherent risks is indispensable. Compressor facilities are integral to the natural gas pipeline system, as they enhance gas pressure to facilitate its movement. Key operations include:

- Gas Compression: Compressors, including centrifugal and reciprocating types, raise the pressure of natural gas, promoting efficient flow through pipelines. Each type of pump has distinct operational characteristics and associated hazards that must be understood to ensure safety.

- Monitoring Systems: Compressor facilities are equipped with advanced monitoring systems that track critical parameters such as pressure, temperature, and gas composition. Familiarity with these systems is essential for identifying anomalies that may signal potential issues.

- Emergency Shutdown Systems: These systems are vital for swiftly halting operations during malfunctions or emergencies. Regular testing and maintenance of these systems are crucial to guarantee their reliability in critical circumstances.

- Common Risks: Compressor stations encounter various risks, including gas leaks, equipment failures, and environmental hazards. Recognizing these risks is fundamental for developing compressor station safety plans and targeted protective measures.

Understanding these operations and risks enables stakeholders to formulate effective protection plans, fostering a culture of security that emphasizes proactive measures. As Desiderius Erasmus wisely stated, 'Prevention is better than cure,' highlighting the importance of proactive protective strategies. For instance, a case study on Damotech underscores the necessity of training employees to identify and report potential hazards, significantly reducing the likelihood of accidents. With approximately 85 forklift-related fatalities each year, the importance of training is undeniable. Furthermore, as Barack Obama remarked, 'The future rewards those who press on,' and Calvin Coolidge asserted, 'Nothing is of greater importance than the conservation of human life.' By cultivating a safety-first mentality, organizations can mitigate risks and enhance operational resilience, ultimately ensuring safer facility operations.

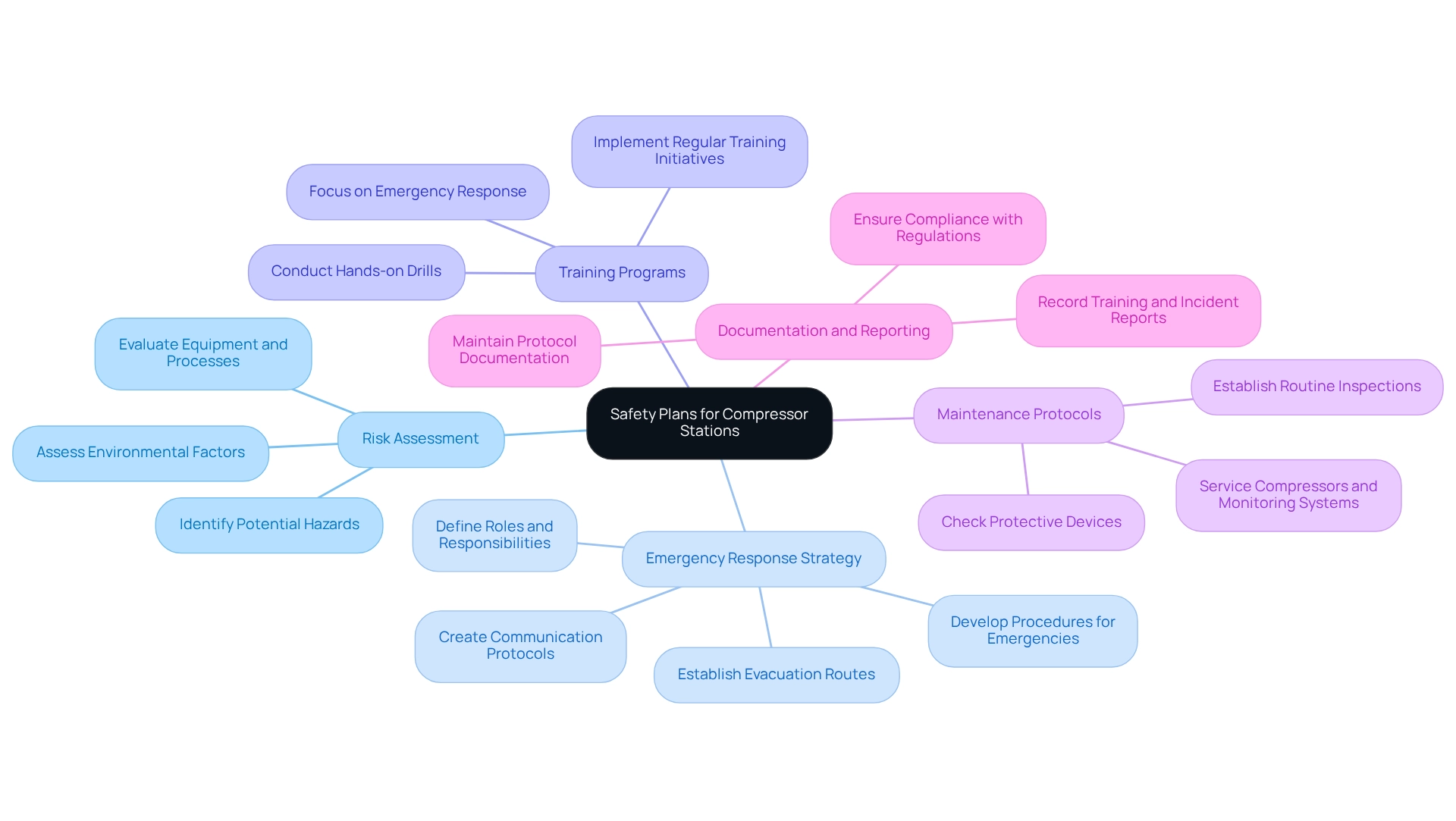

Identify Key Components of Safety Plans

A robust compressor station safety plan must encompass several critical components:

- Risk Assessment: Begin with a comprehensive risk assessment to pinpoint potential hazards linked to compressor operations. This assessment should thoroughly evaluate equipment, processes, and environmental factors.

- Emergency Response Strategy: Develop an all-encompassing emergency response strategy that delineates procedures for various emergency scenarios, such as gas leaks, fires, and equipment failures. This strategy must include evacuation routes, communication protocols, and clearly defined roles and responsibilities.

- Training Programs: Regularly implement training initiatives for all personnel, focusing on procedural guidelines, emergency response, and equipment operation. Tailor training to the specific roles of employees, ensuring it includes hands-on drills for practical understanding.

- Maintenance Protocols: Establish maintenance guidelines for all equipment, emphasizing routine inspections and servicing of compressors, monitoring systems, and protective devices. This proactive approach guarantees that all systems function correctly and mitigates the risk of failure.

- Documentation and Reporting: Maintain thorough documentation of all protocols, training records, and incident reports. This documentation is vital for compliance with regulatory requirements and for the continuous improvement of compressor station safety plans.

By incorporating these elements into protection strategies, facility operators can create a robust framework that enhances safety and compliance.

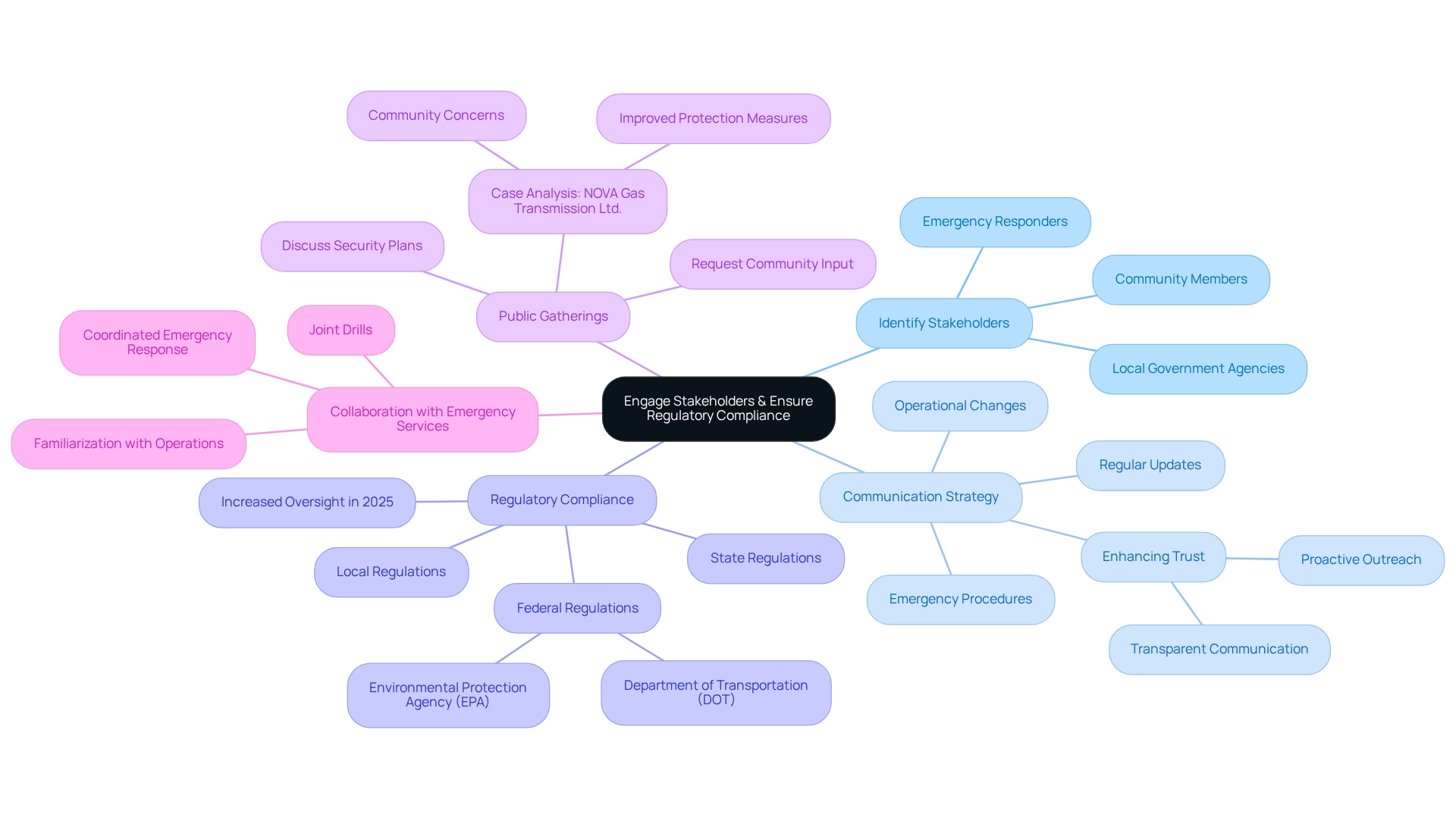

Engage Stakeholders and Ensure Regulatory Compliance

Engaging stakeholders and ensuring regulatory compliance are critical components in successfully implementing compressor station safety plans.

Identify Stakeholders: Recognize all relevant stakeholders, including local government agencies, community members, and emergency responders. Understanding their concerns and expectations is essential for effective engagement.

Communication Strategy: Formulate a comprehensive communication strategy detailing how information will be disseminated to stakeholders. This should include regular updates on security practices, emergency procedures, and any operational changes. Effective communication has been shown to enhance stakeholder trust and participation, with studies indicating that transparent communication can increase community support by up to 30%. Moreover, data on stakeholder involvement in facility protection strategies indicate that proactive outreach can greatly enhance community relations and outcomes.

Regulatory Compliance: Stay informed about local, state, and federal regulations governing compressor station operations. Adherence to standards established by the Department of Transportation (DOT) and the Environmental Protection Agency (EPA) is non-negotiable. In 2025, adherence to these regulations is more critical than ever, as regulatory bodies intensify their oversight. As Ryan Wells, Director of Safety and Damage Prevention, emphasizes, "Preventing harm and keeping people safe, including workers and members of the public, will always be our top priority."

Public Gatherings: Arrange public gatherings to discuss security plans and request input from the community. This openness promotes trust and enables stakeholders to voice their concerns, which can result in enhanced security outcomes. For example, a case analysis concerning NOVA Gas Transmission Ltd. emphasized how community input resulted in improved protection measures after an event at a gas facility. The event highlighted the significance of heeding community concerns, which directly aided in the creation of more efficient protection measures.

Collaboration with Emergency Services: Partner with local emergency services to ensure they are well-acquainted with the facility's operations and emergency response plans. Conducting joint drills not only enhances preparedness but also strengthens relationships with first responders, ensuring a coordinated response in case of an emergency.

By actively involving stakeholders and ensuring adherence to regulations, facility operators can foster a culture of security and responsibility, which includes developing effective compressor station safety plans, ultimately resulting in safer operations and enhanced community relations. Moreover, the organization conveys concern for the recovery of any injured workers, strengthening the commitment to well-being and human welfare in all operational aspects.

Monitor and Evaluate Safety Plan Effectiveness

To ensure the effectiveness of compressor station safety plans, a robust monitoring and evaluation process is essential. Establishing clear performance metrics is crucial to evaluate the effectiveness of protective measures. Key metrics may include incident rates, response times, and compliance with protocols. Regularly reviewing these metrics can highlight trends and areas needing attention.

Conducting frequent audits of practices and procedures pinpoints areas for improvement. These evaluations should assess adherence to established protection plans and regulatory standards, ensuring that all protocols are diligently followed. It is advised to conduct these audits at least every three months to uphold high quality standards.

Implementing feedback mechanisms allows employees and stakeholders to report security concerns or suggest enhancements. This could involve anonymous reporting channels or scheduled meetings focused on well-being, fostering an environment where well-being is prioritized and openly discussed. Management should convey that protection is a top priority, reinforcing a culture of security throughout the organization.

Thoroughly analyzing any incidents or near-misses identifies root causes and implements corrective actions. Recording these analyses is essential for guiding future risk management and preventing recurrence. For example, as demonstrated in the case of Damotech, enabling employees to report damage and promoting a culture of well-being can significantly decrease incidents.

Regularly updating training programs based on evaluation findings and any changes in regulations or technology is vital. Ongoing training guarantees that all staff are equipped with the most recent knowledge and practices related to security, which is essential for upholding a secure working environment.

As Aidan O’Shannessy, The Block Site Manager, aptly stated, "If you don’t know, ask. Working with people is far better than working against them — always bring together all the people and information available to you!" This emphasizes the significance of teamwork in improving protection practices.

By systematically monitoring and assessing the effectiveness of compressor station safety plans, operators can ensure that their precautions remain relevant and effective in mitigating risks. This proactive approach not only enhances workplace safety but also addresses the alarming statistic that forklift accidents account for approximately 85 deaths annually, underscoring the critical need for vigilant safety practices.

Conclusion

Establishing a culture of safety within compressor stations is essential for mitigating risks and ensuring operational integrity in natural gas transportation. A comprehensive understanding of compressor station operations and the potential hazards associated with them lays the foundation for effective safety plans. By focusing on key components such as:

- Risk assessment

- Emergency response

- Training programs

- Maintenance protocols

- Thorough documentation

operators can create a robust safety framework that prioritizes the well-being of personnel and the surrounding community.

Engaging stakeholders and ensuring regulatory compliance are equally vital. By fostering transparent communication and actively involving local communities, compressor station operators can build trust and enhance safety outcomes. Collaborating with emergency services further strengthens preparedness, ensuring that all parties are equipped to respond effectively in case of an incident.

Continuous monitoring and evaluation of safety plans are crucial for maintaining high safety standards. Establishing performance metrics, conducting regular audits, and analyzing incidents help identify areas for improvement and reinforce a proactive safety culture. By committing to these practices, compressor stations can safeguard their operations while contributing positively to community relations and public safety.

Ultimately, prioritizing safety in compressor station operations is not just a regulatory obligation; it is a moral imperative that protects lives and fosters trust within the community. The industry must remain vigilant and dedicated to continuous improvement to navigate the complexities of natural gas operations effectively.

Frequently Asked Questions

What is the role of compressor facilities in the natural gas pipeline system?

Compressor facilities enhance gas pressure to facilitate the movement of natural gas through pipelines, making them integral to the pipeline system.

What are the key operations involved in compressor facilities?

Key operations include gas compression, monitoring systems, and emergency shutdown systems. Gas compression raises the pressure of natural gas, monitoring systems track critical parameters, and emergency shutdown systems halt operations during malfunctions or emergencies.

What types of compressors are used in gas compression?

The types of compressors used include centrifugal and reciprocating compressors, each with distinct operational characteristics and associated hazards.

Why are monitoring systems important in compressor facilities?

Monitoring systems are essential for tracking critical parameters such as pressure, temperature, and gas composition, which helps in identifying anomalies that may signal potential issues.

What is the importance of emergency shutdown systems?

Emergency shutdown systems are vital for swiftly halting operations during malfunctions or emergencies, and regular testing and maintenance of these systems are crucial for ensuring their reliability.

What common risks do compressor stations face?

Compressor stations encounter risks such as gas leaks, equipment failures, and environmental hazards, making it important to recognize these risks for developing safety plans.

How can understanding operations and risks improve safety in compressor facilities?

A thorough understanding of operations and risks enables stakeholders to formulate effective protection plans, fostering a culture of security that emphasizes proactive measures to mitigate risks.

What role does employee training play in safety at compressor facilities?

Employee training is essential for identifying and reporting potential hazards, which significantly reduces the likelihood of accidents, as evidenced by the case study on Damotech.

Why is cultivating a safety-first mentality important for organizations?

Cultivating a safety-first mentality helps organizations mitigate risks, enhance operational resilience, and ultimately ensure safer facility operations.