Overview

Noise abatement for oil sites is critical for compliance with environmental regulations and enhancing operational efficiency. Excessive sound pollution poses significant health risks to local communities. Effective noise management not only helps companies avoid legal repercussions but also fosters positive relationships with stakeholders. This dual benefit contributes to a more sustainable and community-friendly oil industry.

Introduction

In the oil and gas industry, noise pollution presents a formidable challenge that significantly impacts community well-being and regulatory compliance. As operations expand, the urgency for effective noise abatement strategies becomes paramount. With stringent regulations and escalating public concern over health implications, companies must embrace innovative solutions to mitigate noise levels.

This multifaceted approach, which includes advanced technologies and robust stakeholder engagement, is essential for nurturing positive relationships with local communities. This article explores the critical importance of noise abatement, the challenges encountered, and the strategies that can foster a more sustainable and responsible oil and gas sector.

The Importance of Noise Abatement in Oil Operations

Noise abatement for oil sites is an essential aspect of oil activities, heavily influenced by stringent regulations from environmental organizations committed to protecting public health and minimizing disruptions to local communities. In 2025, the impact of sound pollution on public health continues to be a pressing concern, as studies indicate that excessive sound exposure can lead to serious health issues, including chronic stress and hearing loss. These health risks not only threaten community well-being but can also result in significant legal repercussions for companies that fail to manage sound effectively.

Current statistics reveal that sound levels at oil and gas sites frequently exceed permissible limits, with research conducted in states such as Colorado, Pennsylvania, and West Virginia showcasing alarming trends. For example, sound measurements often surpass recommended standards, raising concerns about the long-term effects on nearby residents. This underscores the critical importance of implementing effective noise abatement strategies for oil sites within oil operations.

In 2020, there were 2,179 spills reported in Colorado, New Mexico, and Wyoming, further highlighting the broader environmental concerns associated with oil operations.

Effective sound management practices within the oil and gas sector have demonstrated that implementing noise abatement for oil sites can enhance operational efficiency and foster a favorable corporate image. Companies that actively engage in noise abatement efforts not only comply with regulations but also build trust with stakeholders, including local residents and regulatory bodies. This trust is vital for the success of their projects, as it can lead to smoother operations and community support.

Moreover, the impact of noise abatement for oil sites extends beyond mere compliance; it significantly influences corporate reputation. As noted by Dr. Brian Stacy, a NOAA veterinarian, "Big oil spills are big killers of wildlife and can cause long-lasting damage to marine ecosystems." This statement emphasizes the environmental consequences of oil operations, reinforcing the necessity for effective sound management practices.

In an era where corporate social responsibility is paramount, companies investing in noise abatement for oil sites are perceived more positively by the public. This favorable perception can enhance stakeholder relationships and contribute to long-term sustainability in the industry.

Expert opinions underscore the importance of adhering to regulations governing noise abatement for oil sites. Effective sound management, particularly noise abatement strategies, is not merely a regulatory obligation but a strategic advantage that can distinguish companies in a competitive market. Case studies illustrate that organizations adopting comprehensive sound reduction strategies, such as addressing light pollution from oil and gas operations—which can be so intense that it is visible from space—have experienced improvements in community relations and project outcomes, reinforcing the essential role of sound management in the oil sector.

Additionally, Harbinger Land ensures timely and accurate services tailored to specific client needs, further enhancing efficiency and client satisfaction.

Challenges of Noise Pollution in the Oil and Gas Sector

The oil and gas sector faces significant challenges from sound pollution, a byproduct of its operational activities such as drilling, transportation, and processing. This reality underscores the essential need for noise abatement at oil sites. These activities often generate sound levels that can exceed regulatory limits, creating compliance risks that must be addressed. The remote locations of many oil sites exacerbate the issue, as sound pollution adversely affects local wildlife and surrounding communities, potentially leading to conflicts and increased scrutiny.

In 2025, the variability in sound levels—driven by the type of equipment used and specific operational practices—complicates compliance efforts. For instance, drilling rigs and transportation vehicles can produce sound levels that disrupt local ecosystems and impact human health. As Vyacheslav Popov from Sustainably Yours noted, "With the publication in 2018 of the WHO Environmental sound guidelines for the European Region, there is greater insight into the negative effects of sound on health and a growing awareness of the need to reduce sound pollution."

These guidelines highlight the urgent necessity to mitigate sound pollution.

Furthermore, the lack of standardized sound monitoring practices across the industry hinders effective management. Companies must embrace comprehensive strategies that include regular sound assessments and the adoption of sound-reduction technologies. Real-world examples demonstrate the importance of proactive sound management; for instance, certain operators have effectively integrated sound barriers and advanced equipment designed to minimize auditory output.

The operational conditions for local lines in Europe, characterized by limited infrastructure capacity and high labor costs, further complicate these challenges. Additionally, oil and gas development on Bureau of Land Management (BLM) lands has been reported to cause irreversible damage to wildlands, emphasizing the environmental implications of sound pollution and the urgency for compliance. The glare from oil and gas sites, as illustrated in the case study on light pollution, disrupts local ecosystems and threatens ecological balance.

As the industry evolves, tackling sound pollution challenges through noise abatement at oil sites will be crucial for maintaining compliance and ensuring operational sustainability. Regulatory authorities are increasingly imposing stringent sound level limits for oil operations, necessitating the implementation of innovative sound reduction practices. By prioritizing sound reduction, companies can enhance their operational efficiency while safeguarding the surrounding environment and communities.

Navigating Regulatory Compliance for Noise Control

Navigating regulatory compliance for noise abatement in the oil and gas sector presents a significant challenge, necessitating a comprehensive understanding of the intricate web of federal, state, and local regulations. The Environmental Protection Agency (EPA) has established specific sound level limits that operators must adhere to, with violations potentially leading to substantial penalties, including a full year of noncompliance for breaches of a 12-month standard without prior verification. As we approach 2025, the EPA continues to refine its sound regulations, underscoring the critical nature of noise abatement and the imperative for operators to remain informed about amendments that may impact their operations.

Frank Benjamin-Eze from the EPA noted, "The EPA is proposing certain discrete changes to these particular requirements finalized in the March 2024 final rule," underscoring the ongoing evolution of these regulations.

Compliance extends beyond merely following federal standards; operators must also consider local sound ordinances that may impose stricter limits than federal regulations. This dual-layered approach necessitates regular sound monitoring and reporting, a resource-intensive process that is essential for maintaining compliance and fostering positive community relations.

To effectively navigate this regulatory landscape, operators should establish a robust compliance framework that includes:

- Regular audits to assess adherence to noise regulations.

- Comprehensive employee training programs centered on noise abatement practices.

- The application of advanced sound reduction technologies, which are crucial for significantly mitigating operational noise.

Engaging proactively with regulatory agencies can further streamline compliance processes. By fostering positive relationships with these bodies, operators can gain insights into upcoming regulatory changes and best practices for compliance. The EPA's recent economic impact analyses indicate that while new regulations may affect production levels—projecting a maximum decrease in annual crude oil production of approximately 41.1 million barrels in 2038 and a maximum decrease in natural gas production of about 272.5 million Mcf in 2028—they also present opportunities for companies to innovate and enhance their efficiency.

Case studies illustrate effective compliance frameworks within the oil and gas sector. For instance, the EPA's amendments to the NSPS OOOO and NSPS OOOOa standards have garnered general support from industry stakeholders, emphasizing that these proposed amendments will not significantly impact the implementation of EG OOOOc or the State planning process. This underscores the importance of aligning practices with regulatory expectations.

By adopting a proactive and informed strategy for noise abatement, operators can ensure compliance while contributing to a more sustainable and community-friendly operational model.

Effective Strategies for Noise Reduction in Oil Sites

To effectively implement noise abatement for oil sites, operators can adopt a range of strategies that have proven successful in enhancing compliance and operational efficiency. The installation of sound barriers and enclosures stands out as a highly effective method for noise abatement, capable of significantly reducing sound levels. Recent studies indicate that these barriers can achieve sound reductions of up to 15 decibels, making a substantial difference in minimizing disturbances to surrounding communities.

In addition to barriers, utilizing low-noise equipment is crucial for effective noise abatement. The adoption of advanced machinery designed for quieter operation not only reduces sound generation but also enhances overall efficiency. Regular maintenance of existing equipment, such as installing silencers on compressors and employing vibration-dampening materials, is essential for effective noise abatement and can further enhance sound control efforts.

Scheduling noisy operations during off-peak hours represents another effective strategy for noise abatement, allowing companies to minimize their impact on nearby residents. This approach not only demonstrates corporate responsibility but also fosters better community relations.

Conducting comprehensive sound evaluations is essential for identifying specific sources of disturbance. By understanding the unique acoustic profile of their operations, companies can develop tailored strategies that align with their operational goals. For instance, the polymer and composite materials segment has gained prominence in the industrial sound control market, accounting for a 47.1% value share.

These materials are favored for their lightweight nature and superior acoustic properties, making them ideal for applications such as acoustic foams and vibration damping. The industrial sound control market is moderately fragmented, with major players holding 30% to 35% of the market share, underscoring the competitive landscape and its implications for sound reduction strategies.

As the sector progresses, remaining knowledgeable about noise abatement and the latest advancements in sound reduction technology will be essential. Companies that proactively implement these strategies not only enhance compliance with safety standards but also promote noise abatement, contributing to a more sustainable and community-friendly operational model. As noted by Deloitte, "MarkWide Research is a trusted partner that provides us with the market insights we need to make informed decisions. Their reports are thorough, accurate, and delivered on time. We appreciate their professionalism and expertise, and would highly recommend their services to other companies looking for reliable market research." Additionally, the case study titled 'Use of Composite Material Products Gaining Prominence' demonstrates the practical application and advantages of utilizing composite materials in sound control, enriching the section's depth and relevance.

Leveraging Technology for Enhanced Noise Management

In the oil and gas sector, advanced technologies are essential for effective noise abatement at oil sites. Real-time sound monitoring systems, enhanced by IoT sensors, provide continuous data on sound levels, enabling operators to swiftly address any exceedances. This capability is crucial as the demand for noise abatement and industrial sound control systems in the U.S. is projected to grow at 5.2%, reflecting an increasing emphasis on compliance and safety.

As Patrick McRorie, Chair of Lathrop GPM’s energy practice, observes, "Oil and gas companies are making notable strides when it comes to improving productivity and adopting new technologies." AI-powered analytics further enhance sound management and support noise abatement by identifying patterns and predicting potential impacts stemming from operational changes. This proactive approach allows companies to implement measures before issues arise, thereby safeguarding both regulatory compliance and community relations.

Moreover, integrating innovative sound control technologies—such as active cancellation systems and sound-absorbing materials—plays a crucial role in noise abatement by significantly reducing disturbances at the source. Individual monitoring is essential for contractors and technicians who operate in diverse roles and environments with varying sound exposure. For instance, case studies indicate that regions experiencing industrial growth, like the U.S., China, and India, are witnessing a surge in demand for sound control systems, particularly for noise abatement, due to stricter regulations and heightened awareness of worker safety.

Major companies in the sound mitigation system market, including:

- Compagnie de Saint-Gobain SA

- Honeywell International Inc.

- 3M

- Owens Corning

are leading the charge in developing effective sound management technologies. By utilizing these technologies, oil and gas firms not only improve operational efficiency but also focus on noise abatement, cultivating better connections with nearby populations and ultimately contributing to a more sustainable and responsible industry.

Engaging Stakeholders for Effective Noise Abatement Solutions

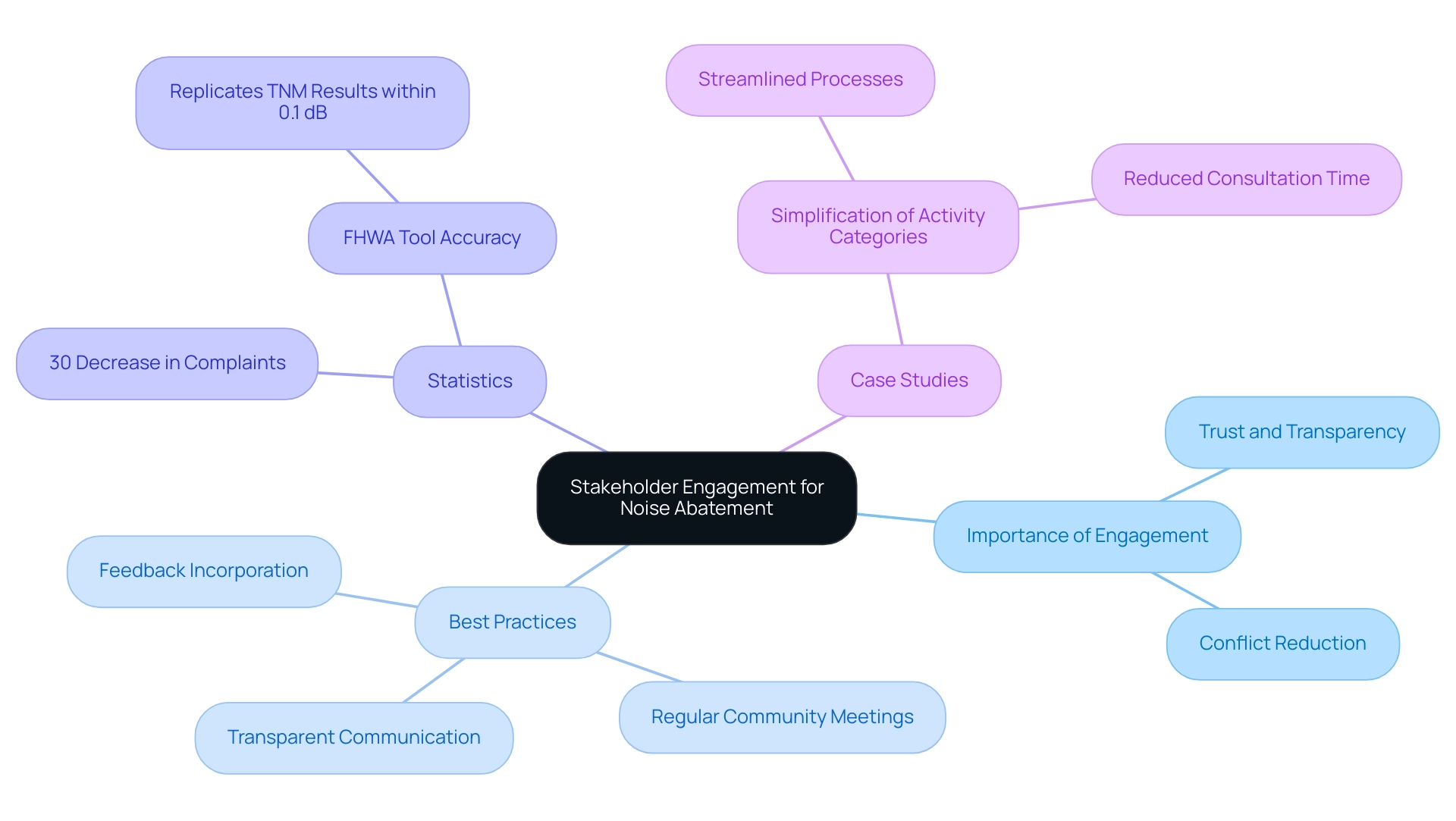

Involving stakeholders is crucial for implementing effective noise abatement at oil sites within the oil and gas industry. Operators must proactively engage with local populations, regulatory agencies, and other stakeholders to gain insights into their concerns regarding sound pollution. Establishing a comprehensive stakeholder engagement plan that includes regular updates, feedback mechanisms, and collaborative problem-solving fosters trust and transparency.

Statistics indicate that successful stakeholder engagement can significantly reduce conflicts related to sound. In 2025, studies show that companies prioritizing community communication experience a 30% decrease in complaints associated with sound pollution. Furthermore, the FHWA's Traffic Sound Screening Tool is noted for its ability to replicate TNM results within 0.1 dB when modeled conditions are consistent, underscoring the importance of precise sound management strategies.

A significant case study emphasizes the Federal Highway Administration's (FHWA) recent suggestion to simplify Activity Categories in traffic sound impact analysis. This initiative aims to streamline processes and reduce the administrative burden on State Departments of Transportation (DOTs), ultimately enhancing stakeholder engagement by providing clearer guidelines and reducing consultation times. Kristin R. White, Acting Administrator of the FHWA, stated, 'In consideration of the foregoing, FHWA proposes to revise 23 CFR part 772 to read as follows,' emphasizing the agency's commitment to enhancing sound regulation implementation.

By prioritizing stakeholder engagement, companies can enhance their reputation, mitigate potential conflicts, and ensure the successful implementation of sound reduction measures. Best practices for stakeholder engagement in the oil and gas sector, such as noise abatement for oil sites, include:

- Transparent communication strategies

- Regular community meetings

- Incorporation of feedback into operational practices

These practices contribute to a more harmonious relationship with the communities they serve. Additionally, the market for acoustic insulation materials, active noise control systems, and noise-canceling headphones offers various tools that can be leveraged for noise abatement at oil sites in the sector.

Conclusion

Noise pollution in the oil and gas industry poses significant challenges that demand immediate and innovative responses. The necessity for effective noise abatement is underscored by stringent regulatory standards and escalating public concern regarding health implications. Companies must recognize that compliance is not merely essential for avoiding legal repercussions; it also plays a critical role in cultivating positive relationships with local communities.

Implementing robust noise management strategies—such as utilizing advanced technologies and engaging with stakeholders—can enhance operational efficiency and improve corporate reputation. By actively addressing noise pollution, companies can foster trust and support from the communities in which they operate, ultimately ensuring long-term sustainability and success.

As the industry evolves, embracing a proactive approach to noise reduction becomes crucial. The integration of innovative technologies, coupled with effective stakeholder engagement, positions oil and gas operators to navigate the complexities of noise management successfully. Prioritizing these efforts allows the industry to mitigate its environmental impact while promoting a healthier and more harmonious coexistence with local communities. The time to act is now; the future of oil and gas operations hinges on a commitment to responsible practices that safeguard both public health and the environment.

Frequently Asked Questions

Why is noise abatement important for oil sites?

Noise abatement is crucial for oil sites to comply with stringent regulations aimed at protecting public health and minimizing disruptions to local communities. Excessive sound exposure can lead to serious health issues, including chronic stress and hearing loss.

What are the health risks associated with sound pollution from oil operations?

Sound pollution can result in chronic stress, hearing loss, and other serious health issues, threatening community well-being and potentially leading to legal repercussions for companies that do not manage sound effectively.

How do sound levels at oil and gas sites compare to permissible limits?

Current statistics indicate that sound levels at oil and gas sites frequently exceed permissible limits, with studies in states like Colorado, Pennsylvania, and West Virginia showing concerning trends in sound measurements.

What are the broader environmental concerns linked to oil operations?

In 2020, there were 2,179 spills reported in Colorado, New Mexico, and Wyoming, highlighting the environmental risks associated with oil operations, including sound pollution's impact on local wildlife and ecosystems.

How does effective sound management benefit oil companies?

Implementing noise abatement strategies can enhance operational efficiency, improve corporate image, and build trust with stakeholders, including local residents and regulatory bodies, leading to smoother operations and community support.

What role does corporate social responsibility play in noise abatement?

Companies that invest in noise abatement for oil sites are viewed more positively by the public, which can enhance stakeholder relationships and contribute to long-term sustainability in the industry.

What challenges does the oil and gas sector face regarding sound pollution?

The oil and gas sector faces challenges from sound pollution due to operational activities that often generate sound levels exceeding regulatory limits, with remote locations exacerbating the issue for local wildlife and communities.

What practices can companies adopt to manage sound pollution effectively?

Companies should embrace comprehensive strategies that include regular sound assessments, adoption of sound-reduction technologies, and the integration of sound barriers and advanced equipment designed to minimize auditory output.

What are the implications of not adhering to noise abatement regulations?

Failing to manage sound pollution can lead to compliance risks, legal repercussions, and damage to corporate reputation, as well as negative impacts on community relations and environmental sustainability.

How are regulatory authorities responding to sound pollution in the oil industry?

Regulatory authorities are increasingly imposing stringent sound level limits for oil operations, necessitating the implementation of innovative sound reduction practices to ensure compliance and operational sustainability.

List of Sources

- The Importance of Noise Abatement in Oil Operations

- Oil and Gas Noise - Earthworks (https://earthworks.org/issues/oil-and-gas-noise)

- 7 ways oil and gas drilling is bad for the environment (https://wilderness.org/articles/blog/7-ways-oil-and-gas-drilling-bad-environment)

- Challenges of Noise Pollution in the Oil and Gas Sector

- 7 ways oil and gas drilling is bad for the environment (https://wilderness.org/articles/blog/7-ways-oil-and-gas-drilling-bad-environment)

- Noise (https://eea.europa.eu/en/topics/in-depth/noise)

- (PDF) STUDY ON THE EFFECT OF NOISE POLLUTION IN THE OIL AND GAS INDUSTRY (https://researchgate.net/publication/327531215_STUDY_ON_THE_EFFECT_OF_NOISE_POLLUTION_IN_THE_OIL_AND_GAS_INDUSTRY)

- Navigating Regulatory Compliance for Noise Control

- Standards of Performance for New, Reconstructed, and Modified Sources and Emissions Guidelines for Existing Sources: Oil and Natural Gas Sector Climate Review (https://federalregister.gov/documents/2024/03/08/2024-00366/standards-of-performance-for-new-reconstructed-and-modified-sources-and-emissions-guidelines-for?ref=ctvc.co)

- Reconsideration of Standards of Performance for New, Reconstructed, and Modified Sources and Emissions Guidelines for Existing Sources: Oil and Natural Gas Sector Climate Review (https://federalregister.gov/documents/2025/01/15/2024-31227/reconsideration-of-standards-of-performance-for-new-reconstructed-and-modified-sources-and-emissions)

- Effective Strategies for Noise Reduction in Oil Sites

- Industrial Noise Control Market 2025-2034 | Size,Share, Growth (https://markwideresearch.com/industrial-noise-control-market)

- Industrial Noise Control Market Size, Trends & Forecast 2025-2035 (https://futuremarketinsights.com/reports/industrial-noise-control-market)

- Leveraging Technology for Enhanced Noise Management

- Oil And Gas Industry Overview: Three Key Trends to Watch in 2025 - Lathrop GPM (https://lathropgpm.com/insights/oil-and-gas-industry-overview-three-key-trends-to-watch-in-2025)

- Monitoring Noise in the Oil & Gas Industry | Cirrus Research plc (https://cirrusresearch.com/monitoring-noise-in-the-oil-gas-industry)

- Noise Mitigation System Market 2025 - Size, Trends And Key Drivers (https://thebusinessresearchcompany.com/report/noise-mitigation-system-global-market-report)

- Industrial Noise Control Market Size, Trends & Forecast 2025-2035 (https://futuremarketinsights.com/reports/industrial-noise-control-market)

- Engaging Stakeholders for Effective Noise Abatement Solutions

- Procedures for Abatement of Highway Traffic Noise and Construction Noise (https://federalregister.gov/documents/2024/10/18/2024-23751/procedures-for-abatement-of-highway-traffic-noise-and-construction-noise)

- Noise Mitigation System Market 2025 - Size, Trends And Key Drivers (https://thebusinessresearchcompany.com/report/noise-mitigation-system-global-market-report)