Overview

Proven strategies for success in gas extraction logistics management are critical in today's dynamic landscape. Effective supply chain management, transportation coordination, and the integration of advanced technologies such as AI and GIS mapping stand out as essential components. These strategies not only enhance operational efficiency but also mitigate risks and ensure timely project completion. Such outcomes are crucial for adapting to the evolving demands of the industry and navigating complex regulatory landscapes.

Consider the complexities of land acquisition, which often involve legal and regulatory challenges. Organizations that implement these proven strategies can effectively address these issues, leading to smoother operations and better project outcomes. The integration of advanced technologies facilitates real-time data analysis, improving decision-making processes and overall project management.

By adopting these innovative approaches, companies can position themselves to thrive amidst industry changes. Embracing effective logistics management strategies is not just beneficial; it is imperative for success in the gas extraction sector. As the industry continues to evolve, those who adapt will lead the way forward.

Introduction

In the dynamic realm of gas extraction, effective logistics management is a fundamental pillar of success. As the industry confronts mounting regulatory pressures, environmental challenges, and the relentless march of technological progress, the capacity to navigate these complexities is crucial.

From the strategic orchestration of supply chains to the incorporation of advanced AI tools, organizations are recognizing that a solid logistics framework not only boosts operational efficiency but also alleviates risks tied to delays and compliance issues.

With a forecasted increase in multimodal freight shipments and a pivot towards sustainable practices, the stakes have never been higher. This article explores the essential components, challenges, and best practices that characterize gas extraction logistics management, offering valuable insights for organizations striving to excel in a competitive landscape.

Understanding Gas Extraction Logistics Management

[[[[[[[Gas extraction logistics management](https://blog.harbingerland.com/the-importance-of-energy-logistics-engineering-in-modern-infrastructure) represents a multifaceted discipline that necessitates strategic planning, execution, and oversight in transporting essential resources and equipment for gas removal operations. This process encompasses the movement of drilling rigs, pipelines, and various materials from suppliers directly to extraction sites. As we approach 2025, the supply chain framework has become increasingly crucial, directly influencing project completion rates and overall operational efficiency.

Recent trends reveal that oil and gas companies are prioritizing capital discipline and technology-driven productivity, essential for managing risks and enhancing project outcomes. A well-organized supply chain framework is vital for gas extraction logistics management to ensure timely project completion while minimizing costs. Key components of this framework include:

- Supply Chain Management: Streamlining the flow of materials and information to ensure that all necessary resources are available when needed.

- Inventory Control: Maintaining optimal inventory levels to prevent shortages or excesses that could disrupt operations.

- Transportation Management: Coordinating the movement of equipment and materials to ensure they arrive at the right place and time.

Effective management of transportation in gas extraction logistics not only boosts operational efficiency but also mitigates risks associated with delays and compliance issues. For instance, firms like Baker Hughes are expanding into low-carbon initiatives, necessitating a strong supply chain approach to support new technologies such as carbon capture and hydrogen generation. Baker Hughes aims for approximately US$6 billion to US$7 billion in new orders by 2030, underscoring the significance of supply chain management in adapting to evolving industry needs.

Furthermore, with multimodal freight shipments projected to rise by 4.6% each year, reaching 19.2 billion tons by 2045, the supply chain landscape in gas production is poised for notable transformation. Additionally, the United Arab Emirates aims to produce 1.4 million tons of green and blue hydrogen annually by 2031, further emphasizing the industry's shift towards low-carbon solutions. As organizations navigate these changes, expert views stress that a robust gas extraction logistics management strategy is vital for success in gas recovery initiatives.

By concentrating on these key components and adapting to current trends, organizations can enhance their project completion rates and ensure sustainable growth in an increasingly competitive environment.

Navigating Challenges in Gas Extraction Logistics

Gas extraction logistics management presents a complex landscape of challenges, particularly in regulatory compliance, environmental stewardship, and resource allocation efficiency. As regulatory frameworks vary significantly across regions, a comprehensive understanding of local laws is essential for successful operations. In 2025, companies will encounter heightened scrutiny regarding compliance, especially with new mandates that require larger organizations to disclose ethnicity and disability pay gaps.

This trend underscores the growing demand for transparency and accountability, particularly in the gas production sector where compliance is paramount.

Environmental considerations are critical, emphasizing the need to minimize ecological impacts and ensure operational safety. The industry must navigate logistical hurdles, including:

- Gas extraction logistics management for remote extraction sites

- The volatility of fuel prices

- Potential supply chain disruptions

These factors can complicate operations significantly, making it imperative for organizations to implement robust risk management strategies.

Proactive measures such as:

- Regular audits

- Stakeholder engagement

- Comprehensive contingency planning

are vital for mitigating risks. As Sean Heinroth, Partner in the Americas Oil & Gas Strategy and Transactions practice at Ernst & Young LLP, notes, "Discipline has really differentiated this current wave of consolidation from previous merger activity." This discipline is essential as organizations adapt to evolving regulatory landscapes and strive to maintain competitive advantages.

Moreover, case studies indicate that legal challenges surrounding regulators' jurisdictional authorities may shift the focus on antitrust supervision and enforcement, further complicating compliance efforts. As state scrutiny intensifies, organizations must remain vigilant in managing risks associated with innovation, consumer protection, and fairness.

Considering these challenges, effective approaches for addressing regulatory compliance problems in gas operations involve utilizing advanced data analytics for monitoring and threat detection within the context of gas extraction logistics management. By adopting these strategies, organizations can enhance their operational resilience and ensure sustainable practices in an increasingly complex regulatory environment.

Leveraging Technology for Efficient Logistics Management

The incorporation of advanced technology in gas extraction logistics management is revolutionizing the industry landscape. AI-powered tools are at the forefront, optimizing route planning, predicting equipment failures, and enhancing inventory management. These innovations not only streamline operations but also significantly reduce costs and improve delivery times.

Consider predictive analytics, which can anticipate supply chain disruptions, enabling companies to adopt proactive measures that mitigate risks.

GIS mapping technology further enhances operational processes by providing accurate tracking of resources and facilitating real-time monitoring. This capability is crucial for maintaining operational efficiency, particularly in a sector where timely responses can make a substantial difference. In fact, the adoption of AI technology in gas production management is projected to grow rapidly, with the Services segment expected to experience a remarkable growth rate of approximately 16% from 2024 to 2029.

C3 AI recently announced the launch of the C3 Generative AI Suite for the oil and gas industry, aimed at improving upstream discovery, asset uptime, and production throughput. This advancement underscores the critical role of AI in enhancing management within the sector.

Real-world applications of these technologies highlight their effectiveness. For example, a significant case study features a gas extraction firm that adopted AI-driven distribution solutions as part of their gas extraction logistics management, resulting in a 30% decrease in operational expenses and a substantial enhancement in delivery times. Such examples illustrate the tangible advantages of integrating technology into supply chain management.

As the sector evolves, embracing digital transformation is no longer an option but a necessity for businesses striving to maintain a competitive edge. Expert insights emphasize that success in the AI-driven oil and gas market hinges on delivering customized, scalable solutions that address the specific challenges faced by the sector. Additionally, with 48% of Gen Z employees indicating plans to leave their positions within the next three to six months, workforce stability remains a pressing concern that could impact management.

The influence of GIS mapping on supply chain efficiency is particularly significant in the context of gas extraction logistics management, as it empowers companies to make informed decisions based on precise data, ultimately leading to enhanced operational outcomes in gas management.

Best Practices for Effective Gas Extraction Logistics

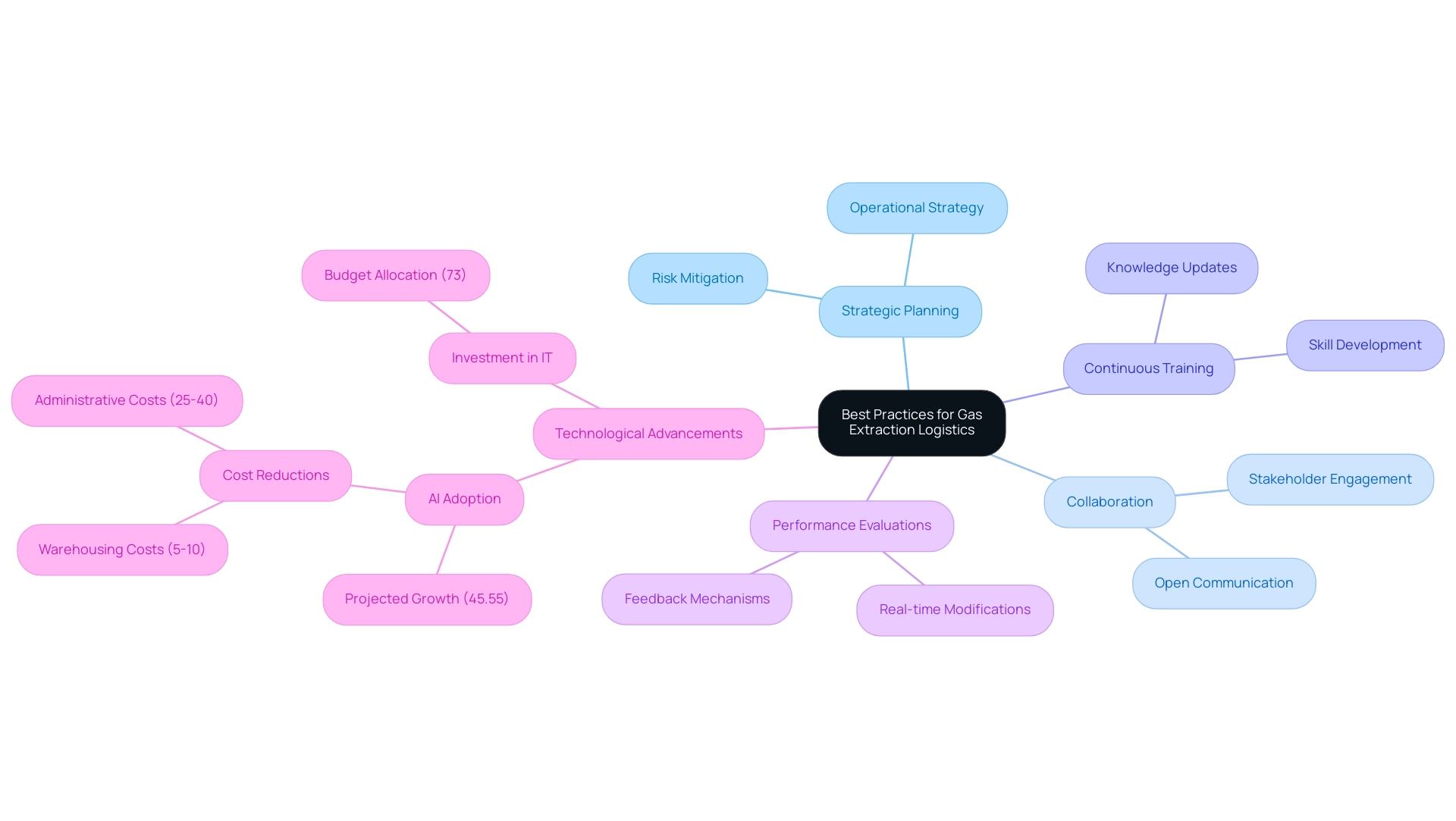

Effective gas extraction logistics management hinges on the implementation of several best practices that are crucial for success in 2025 and beyond. At the forefront is strategic planning, which involves crafting a detailed operational strategy that aligns seamlessly with project objectives and timelines. This proactive approach enhances operational efficiency and mitigates risks associated with unforeseen challenges.

Collaboration among stakeholders—including suppliers, contractors, and regulatory bodies—is equally vital. By fostering open communication and cooperation, companies can streamline operations and ensure that all parties are aligned with the project’s goals. This collaborative environment is essential for navigating the complexities of gas extraction logistics management, particularly in a rapidly evolving market.

Investing in the continuous training and development of supply chain personnel represents another key practice. As the industry evolves, equipping teams with the latest knowledge and skills is imperative for maintaining a competitive edge. This commitment to professional development enhances individual performance and contributes to overall organizational success.

Moreover, regular performance evaluations and feedback mechanisms are essential for identifying areas of improvement. By creating a culture of continuous evaluation, organizations can modify their supply chain strategies in real-time, ensuring they remain responsive to evolving market conditions and operational demands.

Statistics underscore the significance of these practices; for instance, the adoption of AI in supply chains is projected to grow by 45.55% by 2025, driven by the need for enhanced visibility and improved consumer services. This technological advancement can lead to substantial cost reductions, with AI forecasting capable of lowering warehousing costs by 5% to 10% and administrative costs by 25% to 40%. Additionally, Gartner indicates that chief supply chain officers intend to allocate 73% of their supply chain IT budgets to growth and performance improvements in 2023, emphasizing the essential requirement for investment in technology for supply chain management.

Integrating these optimal methods not only improves productivity and profitability but also strengthens operational risk management within the framework of gas extraction logistics management, positioning businesses for sustained success in the competitive field of gas transportation. Furthermore, embracing sustainable practices can further enhance productivity and operational risk management, aligning with broader industry trends and emphasizing the importance of sustainability in logistics management.

Engaging Stakeholders: Strategies for Successful Land Acquisition

Successful land acquisition for gas extraction logistics management projects is fundamentally rooted in effective stakeholder engagement, informed by Harbinger Land's advanced title research solutions. Companies must craft a comprehensive stakeholder engagement plan that identifies key stakeholders, their interests, and potential concerns. This proactive approach facilitates understanding and fosters collaboration.

Open communication is essential. Providing regular updates and engaging in transparent discussions significantly builds trust and mitigates potential conflicts.

Harbinger Land secures accurate leases through diligent research and effective communication, employing GIS mapping and advanced data processing to enhance decision-making. Our process includes conducting thorough preliminary title checks to determine ownership and engaging with potential lessors to educate them about the benefits of domestic energy production. Moreover, employing negotiation strategies that emphasize win-win outcomes is crucial for smoother transactions.

For instance, offering community benefits or proactively addressing environmental concerns can greatly enhance stakeholder buy-in. Statistics indicate that effective stakeholder engagement can lead to a 30% increase in project approval rates, underscoring its importance in the acquisition process.

By nurturing positive relationships with stakeholders and utilizing Harbinger Land's expertise in gas extraction logistics management and acquisitions, organizations can adeptly navigate the complexities of land acquisition, ensuring timely project execution. This strategic focus strengthens stakeholder trust and aligns with the evolving landscape of energy logistics and waste management in 2025, where companies increasingly enhance efficiency through digital technologies and comprehensive land services.

Conclusion

The landscape of gas extraction logistics management presents undeniable complexities, shaped by strategic planning, technological advancement, and stakeholder engagement. Effective logistics management is not just important; it is crucial for enhancing operational efficiency, mitigating compliance risks, and adapting to the ever-evolving demands of the industry. Companies that prioritize a robust logistics framework are strategically positioned to navigate the challenges of regulatory compliance, environmental stewardship, and supply chain disruptions.

Embracing technology, particularly AI and GIS mapping, has emerged as a transformative force in optimizing logistics operations. The integration of these tools streamlines processes, significantly reduces costs, and improves delivery times, ultimately leading to enhanced project outcomes. Furthermore, fostering collaboration among stakeholders and investing in personnel development are essential best practices that contribute to overall success in gas extraction logistics.

As the industry continues to evolve, the adoption of sustainable practices and innovative strategies will be key to thriving in a competitive landscape. Organizations that acknowledge the importance of a comprehensive logistics management approach, coupled with a commitment to continuous improvement and stakeholder engagement, will be well-equipped to meet the demands of the future. In a world where efficiency and accountability reign supreme, the path to success in gas extraction logistics lies in the ability to adapt, innovate, and collaborate effectively.

Frequently Asked Questions

What is gas extraction logistics management?

Gas extraction logistics management is a multifaceted discipline that involves strategic planning, execution, and oversight in transporting essential resources and equipment needed for gas removal operations, including drilling rigs and pipelines.

Why is the supply chain framework important in gas extraction logistics?

The supply chain framework is crucial as it directly influences project completion rates and overall operational efficiency, ensuring timely availability of resources while minimizing costs.

What are the key components of a well-organized supply chain framework in gas extraction logistics?

Key components include Supply Chain Management, Inventory Control, and Transportation Management, which help streamline the flow of materials, maintain optimal inventory levels, and coordinate the movement of equipment and materials.

How does effective transportation management impact gas extraction logistics?

Effective transportation management boosts operational efficiency and mitigates risks associated with delays and compliance issues, ensuring that equipment and materials arrive at the right place and time.

What trends are influencing gas extraction logistics management as we approach 2025?

Trends include a focus on capital discipline, technology-driven productivity, and a shift towards low-carbon initiatives, necessitating a robust supply chain approach to support new technologies.

What are some challenges faced in gas extraction logistics management?

Challenges include regulatory compliance, environmental stewardship, resource allocation efficiency, and logistical hurdles related to remote extraction sites and fuel price volatility.

What proactive measures can organizations take to manage risks in gas extraction logistics?

Organizations can implement regular audits, engage stakeholders, and develop comprehensive contingency plans to mitigate risks associated with operations.

How are regulatory compliance issues evolving in the gas extraction sector?

Companies will face heightened scrutiny regarding compliance, especially with new mandates requiring transparency in areas such as ethnicity and disability pay gaps, making it essential to understand local laws and regulations.

What role does data analytics play in addressing regulatory compliance problems in gas operations?

Advanced data analytics can be utilized for monitoring and threat detection, enhancing operational resilience and ensuring sustainable practices within the complex regulatory environment of gas extraction logistics management.

List of Sources

- Understanding Gas Extraction Logistics Management

- 2025 Oil and Gas Industry Outlook (https://www2.deloitte.com/us/en/insights/industry/oil-and-gas/oil-and-gas-industry-outlook.html)

- 100 Jaw-Dropping Supply Chain & logistics Statistics to know - DocShipper (https://docshipper.com/logistics/100-supply-chain-logistics-statistics)

- Navigating Challenges in Gas Extraction Logistics

- 3 trends shaping oil, gas and chemicals in 2025 (https://ey.com/en_us/insights/oil-gas/oil-and-gas-and-chemicals-industry-outlook)

- Top 10 Compliance Challenges in 2025 | Skillcast (https://skillcast.com/blog/top-10-compliance-challenges-2025)

- Ten Key Regulatory Challenges of 2025 (https://kpmg.com/us/en/media/news/key-regulatory-challenges-for-2025.html)

- Leveraging Technology for Efficient Logistics Management

- AI In Oil And Gas Market Size | Mordor Intelligence (https://mordorintelligence.com/industry-reports/ai-market-in-oil-and-gas)

- 90+ Stats About Logistics, Manufacturing, and Automation You Must Know (2025 Edition) (https://cyngn.com/blog/90-stats-about-logistics-manufacturing-and-automation-you-must-know-2025-edition)

- Best Practices for Effective Gas Extraction Logistics

- Oil and Gas Logistics Market Report 2025, Market Size, Share, Growth, CAGR, Forecast, Revenue (https://cognitivemarketresearch.com/oil-and-gas-logistics-market-report?srsltid=AfmBOop1ecHWrrQ-j88sfIctzMDZATcUxZdR-j2DVkgrz7KePeiJESur)

- Supply Chain Statistics — 70 Key Figures of 2025 (https://procurementtactics.com/supply-chain-statistics)

- Engaging Stakeholders: Strategies for Successful Land Acquisition

- Project 2025 — Department of Energy and Related Commissions — Annotated – Environmental Data and Governance Initiative (https://envirodatagov.org/project-2025-department-of-energy-and-related-commissions-annotated)

- 2025 Oil and Gas Industry Outlook (https://www2.deloitte.com/us/en/insights/industry/oil-and-gas/oil-and-gas-industry-outlook.html)