Overview

Implementing effective noise control for battery systems involves a structured approach that includes conducting sound assessments, identifying noise sources, selecting appropriate strategies, and continuously monitoring effectiveness. The article emphasizes that addressing both electrical and mechanical disturbances is crucial for enhancing operational efficiency and longevity of battery systems, supported by evidence showing that noise can degrade performance and safety.

Introduction

In the intricate world of battery systems, noise is more than just an annoyance; it can significantly impact performance and longevity. From electrical fluctuations that disrupt management systems to mechanical sounds that signal wear and tear, understanding the sources and effects of noise is essential for optimizing battery efficiency.

As organizations strive to enhance their energy solutions, addressing noise through innovative strategies and technologies becomes paramount. This article delves into the types of noise affecting battery systems, identifies common sources, and outlines effective noise control measures, ultimately highlighting the importance of a systematic approach to ensure reliability and safety in energy storage solutions.

Understanding Noise in Battery Systems

Sound in power storage units is mainly classified into two categories:

- Electrical disturbances, arising from variations in voltage and current

- Mechanical disturbances, created by components such as fans and pumps

Comprehending these differences is essential, as both kinds of interference can greatly hinder energy performance. For example, electrical disturbances can interfere with the battery management system, resulting in flawed readings that could compromise operational efficiency.

Recent statistics from Data in Brief, Volume 58, 2025, Article 111216 indicate that electrical interference can lead to performance degradation by as much as 15%, underscoring the importance of addressing these issues. Meanwhile, mechanical sounds contribute to the wear and tear of physical components, potentially leading to premature failures. Ethan R. Brush, a principal market leader in energy, environmental, and transportation sectors, emphasizes the importance of addressing these challenges:

I really enjoy the technical aspect of my work, and I love using math and science to calculate an outcome and then test those predictions in the real world.

This technical foundation is crucial for identifying effective noise control for battery systems measures. Furthermore, the normalization of data to standard ranges across simulation runs enhances the reliability of disturbance management strategies. The recent experimental design focused on examining the threshold at which adversarial interference signals disturb state-of-charge estimation processes emphasizes the critical importance of understanding disruptions in energy storage units.

Adherence to regulatory standards, as demonstrated in the case study on energy storage technologies, illustrates that compliance not only promotes safety but also enhances the operational integrity of energy storage units. Identifying and prioritizing the management of both electrical and mechanical disturbances is crucial for stakeholders seeking noise control for battery systems to improve energy cell performance.

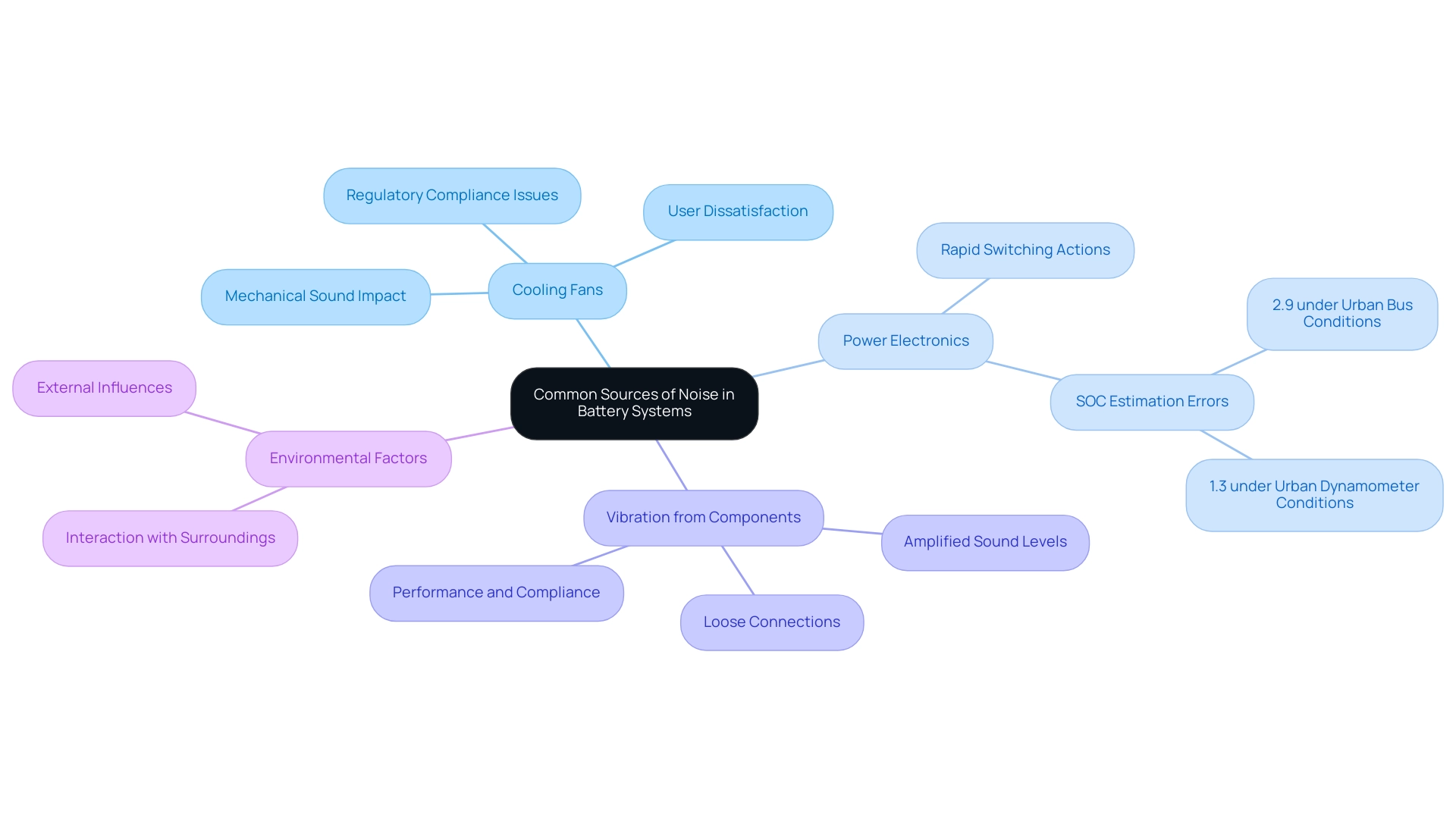

Identifying Common Sources of Noise in Battery Systems

Recognizing the common origins of disturbance in battery systems is essential for effective noise control for battery systems and sound reduction strategies. The primary culprits include:

- Cooling Fans: Essential for maintaining optimal thermal conditions, these fans can produce significant mechanical sound, impacting operational efficiency. Engineers frequently highlight their importance, mentioning that excessive sound can result in user dissatisfaction and possible regulatory issues. Martinet et al. have emphasized the significance of tackling these sound issues to ensure compliance with safety standards.

- Power Electronics: Components such as inverters and converters are important factors in electrical disturbances, primarily because of their rapid switching actions. This sound can disrupt other operations and must be carefully managed. Recent statistics indicate that under different driving conditions, SOC estimation errors can attain as high as 2.9%, highlighting the necessity for effective management of disturbances to improve operational efficiency.

- Vibration from Components: Loose connections or inadequately secured parts can induce vibrations, which in turn amplify sound levels throughout the setup. Tackling these concerns is essential for both performance and adherence to noise control for battery systems standards. The case study on 'Requirements for Commercial Sound Measurement Frameworks' illustrates how a well-structured measurement setup can aid in effective diagnostics, ultimately enhancing power performance.

- Environmental Factors: External influences, such as wind or adjacent machinery, can also elevate the overall sound profile. For example, as emphasized in recent research, the interaction between energy storage units and their surroundings can worsen sound levels, affecting user experience. By thoroughly understanding these sound sources, stakeholders can implement targeted control measures, improving both operational efficiency and user satisfaction.

The Impact of Noise on Battery Performance and Longevity

Excessive sound in energy storage systems can result in significant adverse effects, including:

- Reduced Efficiency: Sound interference can disrupt the energy management system, leading to diminished performance and energy losses. Recent studies suggest that noise control for battery systems is crucial, as sound levels directly correlate with power efficiency, illustrating how elevated decibel levels can impede optimal operation. Significantly, the suggested SOC prediction technique has demonstrated a reduction of Max by 71.8% relative to the gate recurrent unit (GRU) approach and by 26.1% in comparison to the recurrent neural network (RNN) approach, highlighting the significance of controlling interference for optimal energy performance.

- Reduced Lifespan: Ongoing exposure to elevated sound levels may cause mechanical wear and affect essential parts, ultimately diminishing the lifespan of the power source. For instance, powering one LED street lamp for just one hour would require approximately 2,483 transducer units, highlighting the extensive energy demands that could be affected by noise-related issues.

- Safety Risks: Noise control for battery systems is crucial, as excessive sound can obscure warning signals or alarms, which might result in hazardous situations. This concern is especially pertinent in settings where energy storage units function under high stress. A case study carried out in Alexandria, Egypt, assessed sound levels along a major roadway, providing insights into how urban sound pollution can impact various frameworks, including energy storage solutions. By proactively tackling sound issues with effective noise control for battery systems, organizations can significantly improve the reliability and safety of their power units, reducing risks and enhancing overall performance. Moreover, energy storage is vital in enhancing grid reliability by offering frequency response, addressing short-term demand surges, and optimizing renewable energy utilization, thereby highlighting the wider significance of noise control for battery systems in energy frameworks. In the context of innovative designs, the Urban Transducer, created by Ryan Browne, Nathanael Dunn, Daniel Nelson, and Benjamin Scholten, exemplifies how modern approaches can address these challenges.

Strategies and Technologies for Effective Noise Control

Applying successful techniques for noise control for battery systems is vital for enhancing their performance. Here are several key approaches:

-

Soundproofing Materials: Utilizing advanced sound-absorbing materials, such as insulation combined with a triple soundproofing mat (made of butyl, aluminum, and sound-insulating material), has shown to be particularly beneficial.

Recent studies suggest that this combination can attain an average reduction of 9.0 dB at the target frequency of 560 Hz. As emphasized by Eun-Sung Song, the author of the study,

Our research indicates that, taking into account the attributes of sound from milling machines, this combination is more effective in sound reduction than any other tested soundproofing strategy.

Furthermore, these soundproofing technologies could be modified to establish sound barriers intended at reducing disturbances from freight trains, which is an area of growing interest for many organizations.

-

Vibration Dampening: Implementing rubber mounts or isolation pads can significantly minimize vibrations generated by mechanical components, enhancing overall sound control.

-

Active Sound Cancellation: This technology utilizes opposing sound waves to actively lessen sound levels, providing a sophisticated solution for managing unwanted audio.

-

Regular Maintenance: Conducting routine inspections ensures that all components are securely mounted and functioning properly, which is essential for maintaining sound control.

Moreover, small gaps in walls around electrical outlets, light switches, or cable openings can act as pathways for sound. A case study revealed that sealing these gaps can enhance soundproofing effectiveness by up to 10-15%. The study discovered that addressing these gaps significantly enhanced overall sound control, demonstrating a practical application of soundproofing strategies.

By utilizing these strategies, organizations can greatly reduce sound levels in energy storage solutions, which is essential for effective noise control for battery systems, in line with the latest progress in sound management technologies, including cutting-edge materials and methods that are consistently being developed in the field.

Step-by-Step Implementation of Noise Control Measures

Implementing effective noise control for battery systems requires a structured approach. Here’s a step-by-step guide:

-

Conduct a Sound Assessment: Utilize a sound level meter to measure sound levels, helping to identify problem areas.

This initial assessment is crucial as it sets the foundation for subsequent actions. Notably, preamplifier gains in acoustic emission testing typically range around 40 dB, with reported values from 34 to 60 dB, highlighting the need for precise measurement techniques.

-

Identify Sources: Pinpoint specific components that contribute to excessive sound, such as cooling fans or mechanical vibrations. Comprehending the source is crucial to identifying successful solutions. Acoustic emission (AE) has shown to be effective in identifying internal damage mechanisms in lithium-ion batteries (LIBs) subjected to thermal abuse, which underscores the importance of noise control for battery systems in addressing sound-related problems.

-

Select Appropriate Strategies: Choose sound control strategies based on identified sources. For example, if vibration is a major contributor, consider implementing vibration dampeners or isolation mounts.

-

Install Noise Control Solutions: Once strategies are selected, proceed to install solutions like soundproofing materials or acoustic barriers. These installations should be designed to fit the specific needs of the system, ensuring optimal performance.

-

Test and Evaluate: After implementation, reassess sound levels to evaluate the effectiveness of the measures taken. This step is vital to ensure that the solutions are achieving the desired outcomes.

-

Adjust as Necessary: If sound levels remain high, revisit the initial assessment and refine your approach. Continuous improvement is essential, as Anna Pražanová emphasizes the significance of thorough investigation and data curation in her work on sound management.

This iterative process is essential for effective sound management. This systematic method not only assists in effective sound control but also supports noise control for battery systems by minimizing disruptions and improving operational safety.

Monitoring and Evaluating Noise Control Effectiveness

To maximize the effectiveness of sound control measures in battery systems, consider implementing the following monitoring strategies:

- Regular Sound Surveys: Conducting periodic assessments is crucial for quantifying sound levels and detecting any significant changes. These surveys not only help in maintaining compliance with safety standards but also contribute to the overall operational efficiency of energy sites. As emphasized by the prediction that smart electric vehicles could decrease carbon dioxide emissions by up to 43% compared to diesel engine vehicles, effective sound management is essential to minimize environmental impact.

- Feedback Mechanisms: Establishing robust channels for operators and maintenance personnel to report sound issues is essential. This fosters a culture of awareness and responsibility, where team members can actively participate in reducing disturbances.

- Adjust Control Measures: It is vital to remain flexible and responsive to monitoring results. Be prepared to modify or enhance sound control strategies as necessary. This adaptability is essential considering the dynamic nature of energy operations and the ongoing evolution of sound reduction technologies.

- Documentation: Maintaining comprehensive records of sound assessments and adjustments to control measures is important for future reference. This documentation not only aids in tracking the effectiveness of implemented strategies but also serves as a valuable resource for compliance audits and ongoing improvement initiatives.

A case study on the Development of Cloud Battery Management System illustrates this point. Using IoT and cloud computing, this framework has notably improved diagnostics and management of energy storage solutions, validating estimation algorithms for lithium-ion and lead-acid power sources, and could act as a model for incorporating sound control technologies.

By adopting these strategies, organizations can ensure optimal performance in sound management, effectively addressing any emerging issues while maintaining a commitment to safety and regulatory compliance. Regular noise surveys play a pivotal role in noise control for battery systems, as emphasized by industry expert Qingyu Zhang, who states, 'The importance of regular noise assessments cannot be overstated in the contemporary landscape of noise control for battery systems management.' This highlights their critical role in enhancing both operational efficiency and environmental responsibility.

Conclusion

Addressing noise in battery systems is not merely a technical challenge; it is a vital component of ensuring optimal performance and longevity. The article outlines the two primary types of noise: electrical and mechanical, both of which can disrupt battery management systems and lead to inefficiencies and premature failures. Identifying common sources of noise, such as:

- Cooling fans

- Power electronics

- Environmental factors

is essential for the development of targeted noise mitigation strategies.

Implementing effective noise control measures, including:

- Soundproofing materials

- Vibration dampening

- Regular maintenance

can significantly enhance operational efficiency and user satisfaction. A structured approach to noise control—from conducting assessments to selecting and testing solutions—ensures that organizations can systematically address noise issues. Continuous monitoring and evaluation of these measures are crucial for adapting to new challenges and maintaining compliance with safety standards.

Ultimately, the insights presented highlight the critical importance of a comprehensive noise management strategy in battery systems. By prioritizing noise control, stakeholders can not only improve the performance and reliability of energy storage solutions but also contribute to a safer and more efficient energy landscape. As the industry evolves, embracing innovative technologies and strategies will be key to overcoming noise-related challenges and optimizing battery systems for the future.

Frequently Asked Questions

What are the two main categories of sound in power storage units?

The two main categories of sound in power storage units are electrical disturbances, which arise from variations in voltage and current, and mechanical disturbances, which are created by components such as fans and pumps.

Why is it important to understand the differences between electrical and mechanical disturbances?

Understanding the differences is essential because both types of interference can significantly hinder energy performance. For instance, electrical disturbances can affect the battery management system, leading to faulty readings and compromised operational efficiency.

How much can electrical interference degrade performance?

Recent statistics indicate that electrical interference can lead to performance degradation by as much as 15%.

What are some common sources of mechanical sound in battery systems?

Common sources of mechanical sound include cooling fans, power electronics (like inverters and converters), vibrations from components, and environmental factors (such as wind or adjacent machinery).

What role do cooling fans play in power storage units?

Cooling fans are essential for maintaining optimal thermal conditions, but they can produce significant mechanical sound that impacts operational efficiency and may lead to user dissatisfaction or regulatory issues.

How do power electronics contribute to electrical disturbances?

Power electronics, such as inverters and converters, contribute to electrical disturbances primarily through their rapid switching actions, which can disrupt other operations.

What can cause vibrations in battery systems?

Vibrations can be caused by loose connections or inadequately secured parts, which can amplify sound levels throughout the setup.

How can environmental factors affect sound levels in battery systems?

External influences, such as wind or noise from adjacent machinery, can elevate the overall sound profile of energy storage units, potentially worsening user experience.

What is the significance of adhering to regulatory standards in energy storage technologies?

Adherence to regulatory standards promotes safety and enhances the operational integrity of energy storage units, which is crucial for effective noise control and performance improvement.

What is emphasized in the recent experimental design related to disturbance management?

The recent experimental design focuses on examining the threshold at which adversarial interference signals disturb state-of-charge estimation processes, highlighting the importance of understanding disruptions in energy storage units.